Apparatus and method for measuring glass micro-bead refractive index

A technology of glass beads and refractive index, which is applied in the field of measurement, can solve the problems of unfavorable light coaxial adjustment, glass beads falling off, adjustment errors and increased measurement errors, etc., to achieve non-toxic measurement process, convenient adjustment, and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

[0041] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

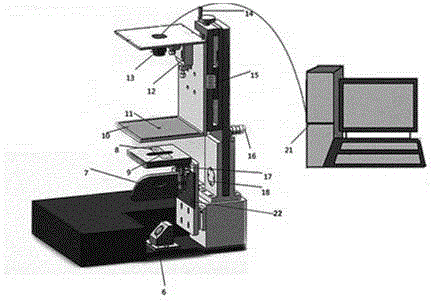

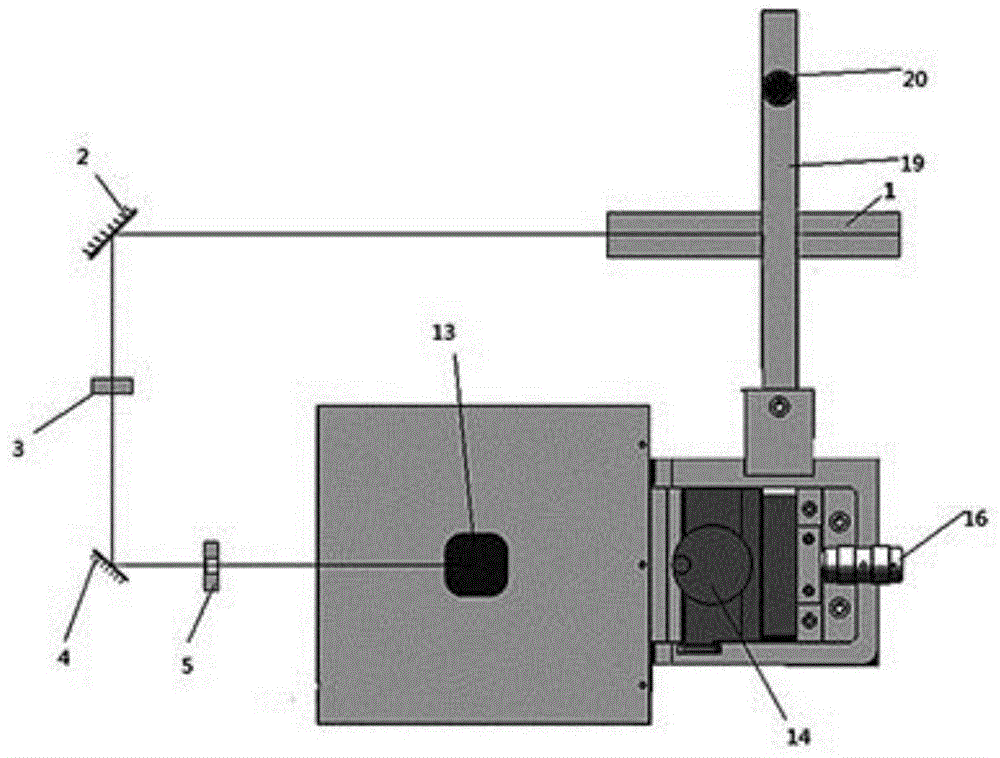

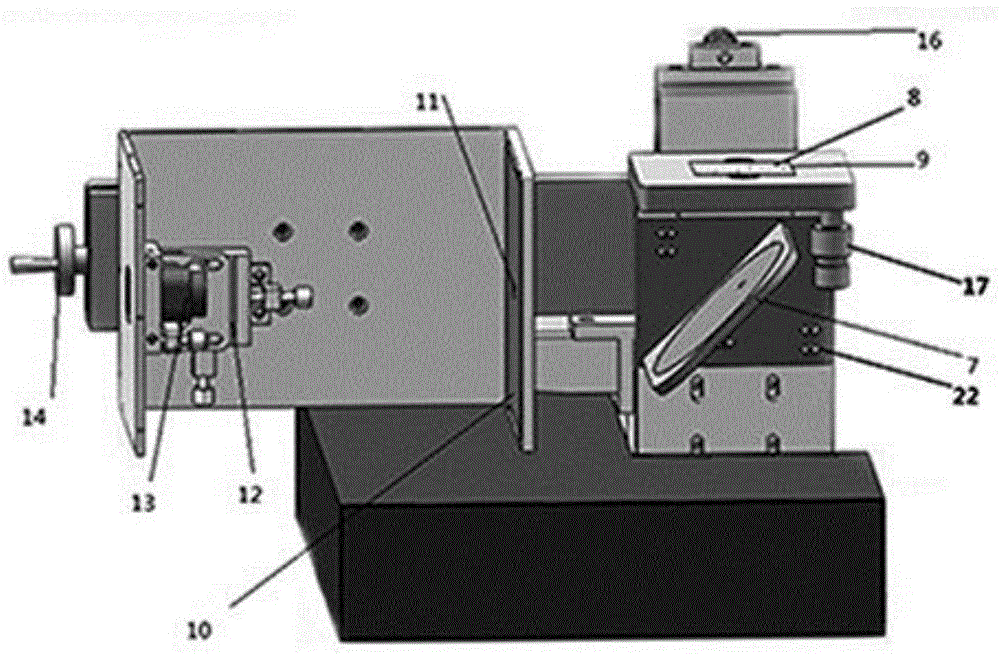

[0042] In Fig. 1 (a), the first reflector 2, the second reflector 4, the third reflector 6, and the perforated reflector 7 are all placed at 45° to the optical axis, and the laser 1 emits laser light, which is captured by the first reflector 2 Reflected by the lens 3, the transmitted light is reflected by the second reflector 4, and the light beam passing through the aperture 5 is reflected by the third reflector 6 in Fig. The hole reflector 7 transmits the slide glass 9 on the stage, and uses the X, Y translation structure 17 to adjust the glass beads 8 on the slide glass 9, so that the laser beam is irradiated on the glass beads 8, so that the glass beads 8 on the receivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com