Method for preparing cefepime dihydrochloride

A technology of cefepime hydrochloride and cephalosporin, applied in the field of preparation of cefepime hydrochloride, can solve the problems of insufficient supply, high price, inconvenient post-processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

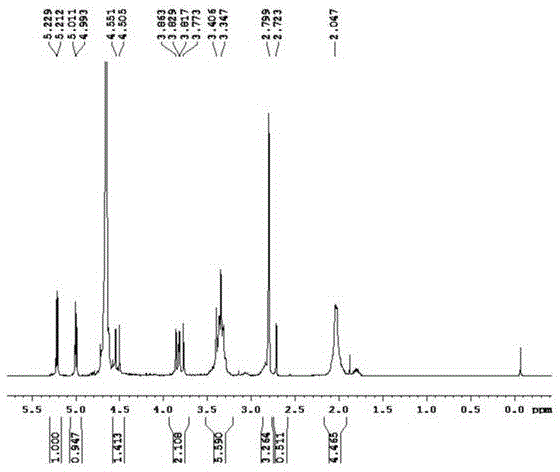

Image

Examples

Embodiment 1

[0015] Example 1 A preparation method of cefepime hydrochloride. The steps and conditions are as follows:

[0016] The invention provides a preparation method of cefepime hydrochloride. The steps and conditions are as follows:

[0017] (1) The raw materials are: 7-Aminocephalosporanic acid (abbreviated as 7-ACA), hexamethyldisilazane (abbreviated as HMDS), trimethyliodosilane (abbreviated as TMSI), N-methylpyrrolidine (abbreviated as NMP); CH 3 OH (methanol); the mass ratio of raw material components is 7-ACA: HMDS: catalyst: TMSI: NMP: CH 3 OH=1:3:0.02:1.8:3:1; the catalyst is 95% hydrochloric acid;

[0018] (2) The crude product of cefepime hydrochloride was prepared as follows: According to the mass ratio of raw materials, under the protection of dry nitrogen, add 5.0g of 7-ACA to a dry 100mL three-necked flask, press CH 3 OH mass g: the volume of anhydrous dichloromethane mL is 1: 50 Add anhydrous dichloromethane, stir, heat at 45°C for 3 h, add 15 g of HMDS, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com