Opening and closing chuck

一种卡盘、机械手的技术,应用在卡盘、夹固、支承等方向,能够解决壳体强度降低、壳体加工繁杂、活塞误动作等问题,达到机构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

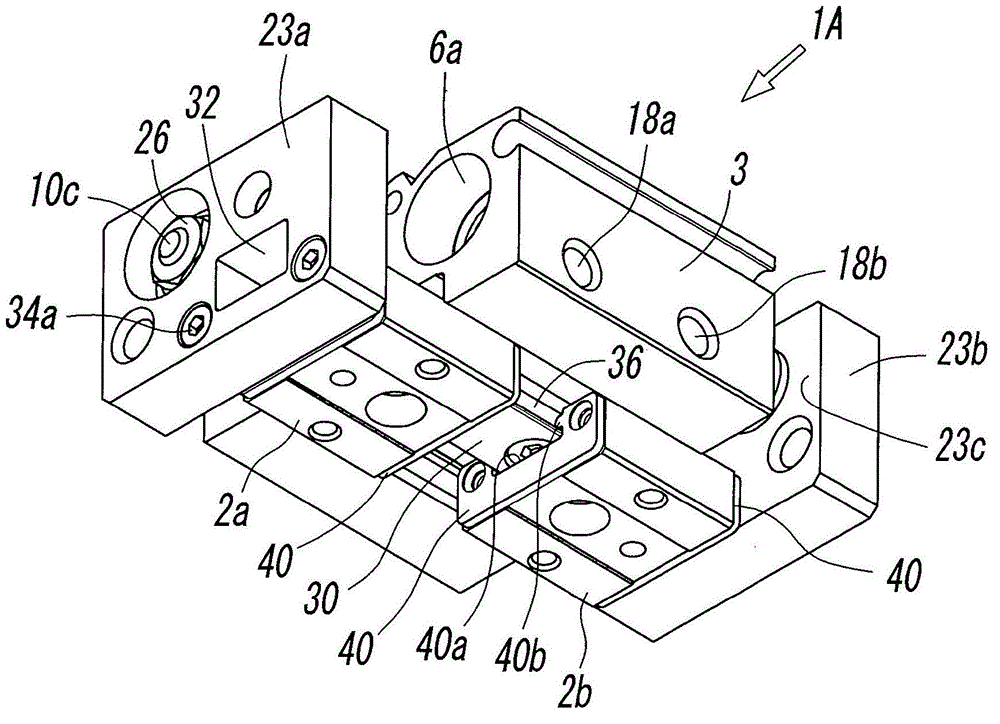

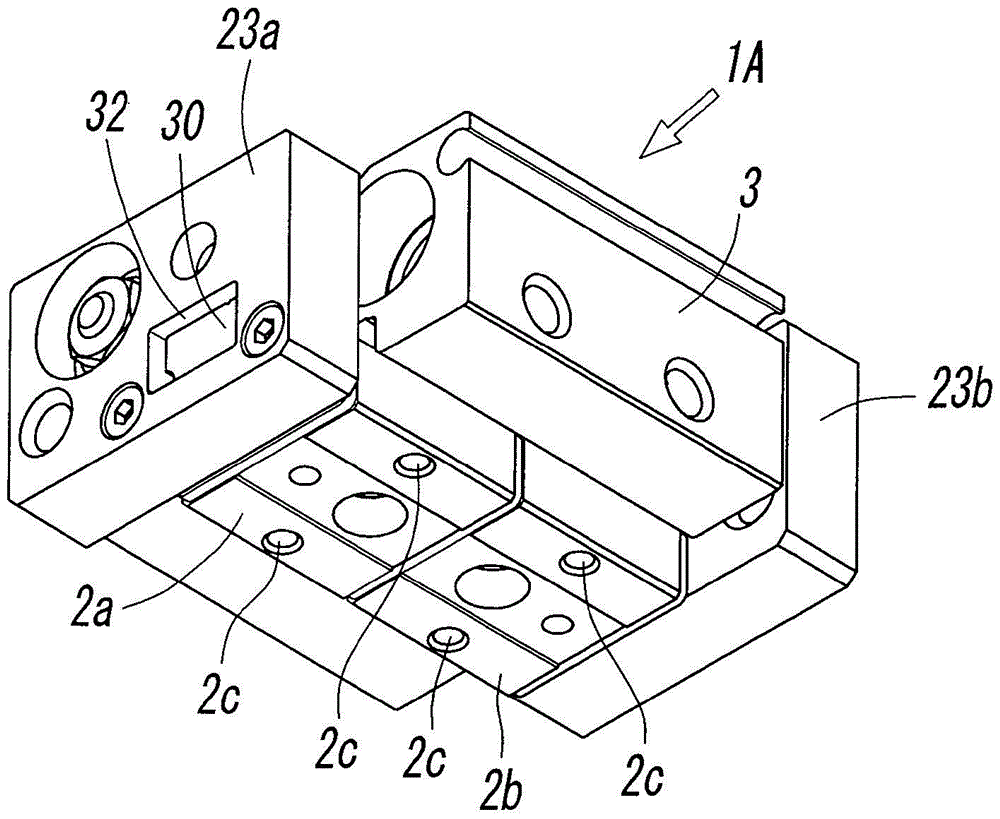

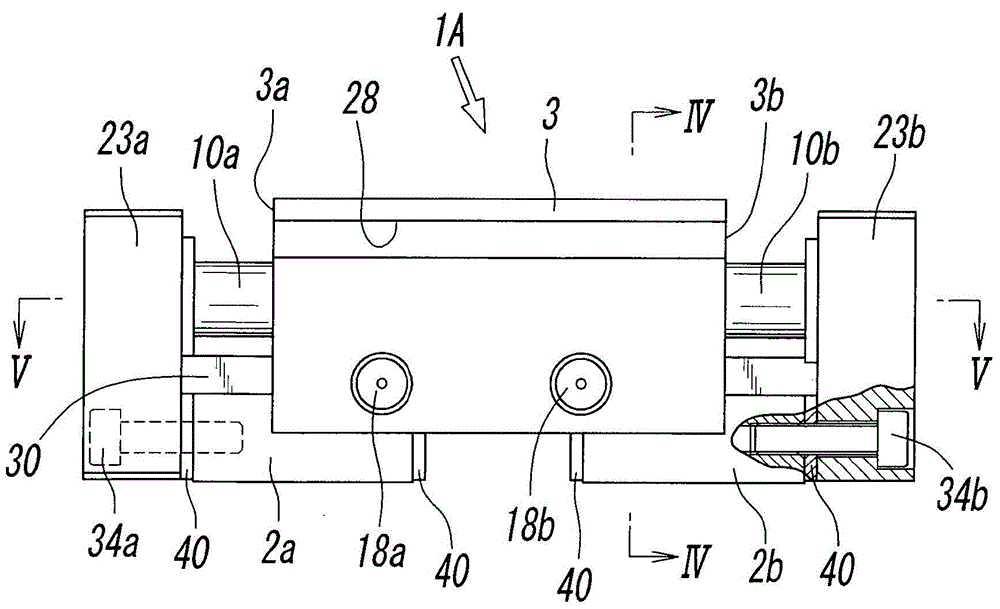

[0039] Figure 1 to Figure 7 It is a figure showing the first embodiment of the opening and closing chuck of the present invention. The opening and closing chuck 1A of the first embodiment is an asynchronous operation in which two manipulators 2a and 2b independently and asynchronously perform opening and closing operations. The opening and closing chuck of the type is an opening and closing chuck of the same thrust type in which the holding forces (thrust) acting on the above-mentioned two manipulators 2a, 2b are equal to each other.

[0040] The above-mentioned opening and closing chuck 1A has a chuck main body 3 formed as a substantially rectangular block in plan view, and inside the chuck main body 3, first and second two air cylinder devices are arranged in parallel with each other. 4a, 4b. That is, in the interior of the chuck main body 3, the first cylinder hole 6a and the second cylinder hole 6b parallel to each other are formed from the first end 3a side of the chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com