A kind of automatic steel sample grinding machine and using method thereof

A grinding machine and steel sample technology, which is applied to the parts of grinding machine tools, grinding automatic control devices, grinding machines, etc., can solve the problems of high labor intensity, long waiting time for molten steel, and affecting the continuous rhythm of steelmaking and continuous casting, etc., to achieve Reduce labor intensity, reduce sample waiting time, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

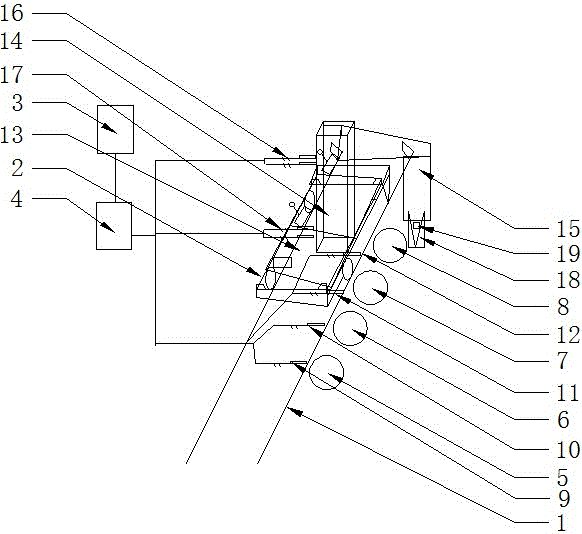

[0019] see figure 1 , an automatic steel sample grinding machine, including track 1, fast grinding sample car 2, man-machine control screen 3, long-distance PLC control unit 4, hot pattern clamping table 5, water immersion cooling table 6, flat rough grinding wheel machine 7 Flat fine grinding wheel machine 8, the hot pattern clamping table 5, water immersion cooling table 6, flat rough grinding wheel machine 7 and flat flat fine grinding wheel machine 8 are installed on the right side of track 1 successively from back to front, and the hot pattern clamping Platform 5, water immersion cooling platform 6, flat coarse grinding wheel machine 7 and flat fine grinding wheel machine 8 are respectively equipped with thermal pattern clamping platform detection limit 9, water immersion cooling platform detection limit 10, flat Type rough grinding machine d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com