Six-axis Swiss type milling machine tool

A machine tool, turning and milling technology, which is applied in the field of six-axis center turning and milling machine tools, can solve the problems that the forming time of tool workpieces is not well optimized and affects the forming efficiency of workpieces, and achieves the optimization of forming time, which is conducive to maintenance and optimization The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

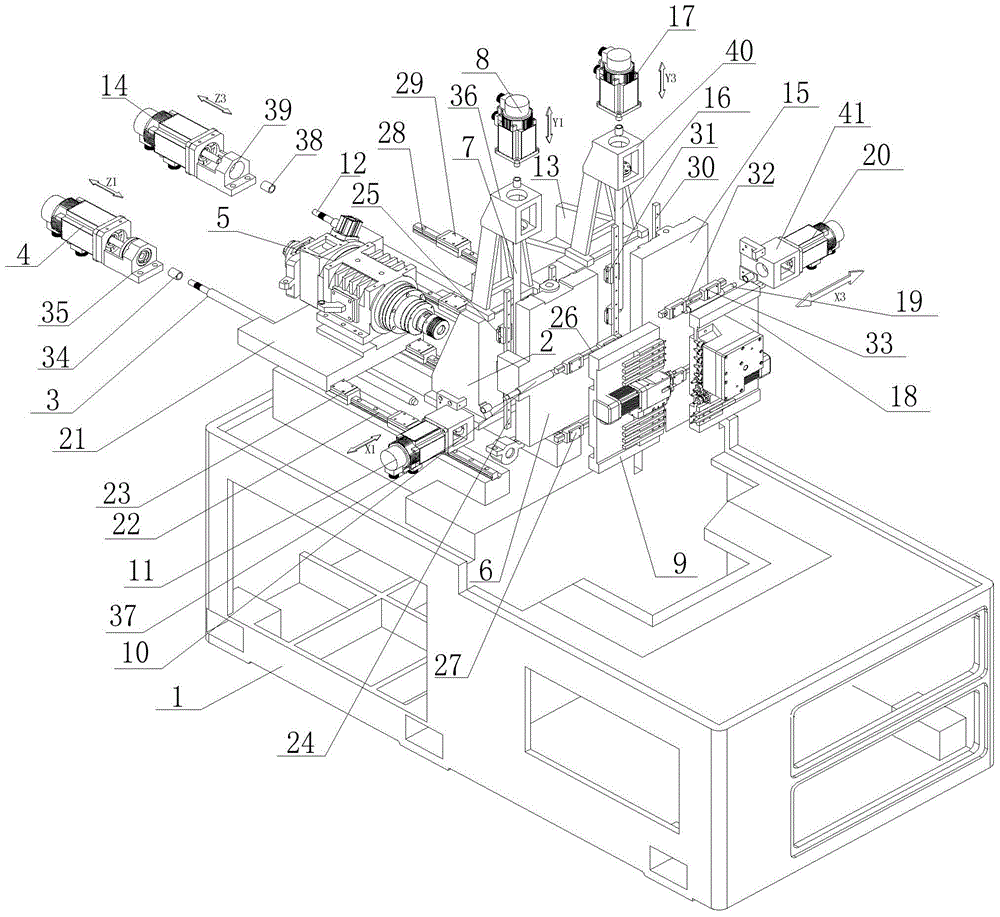

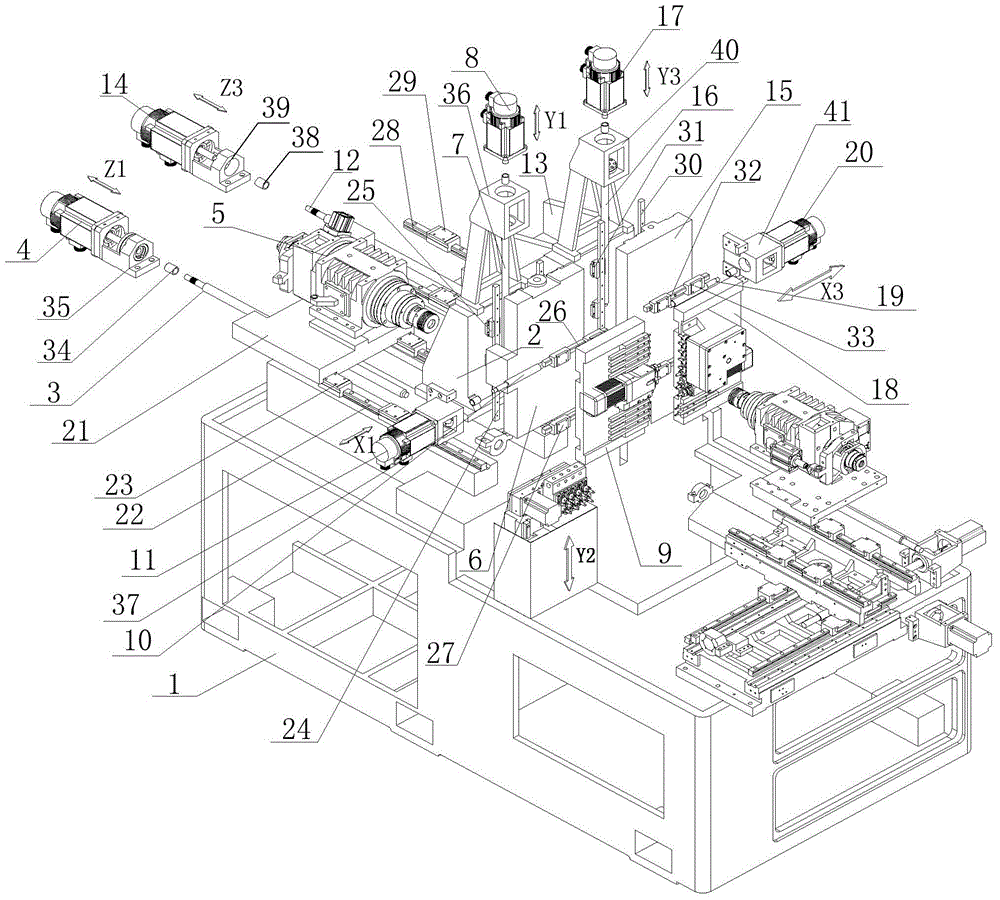

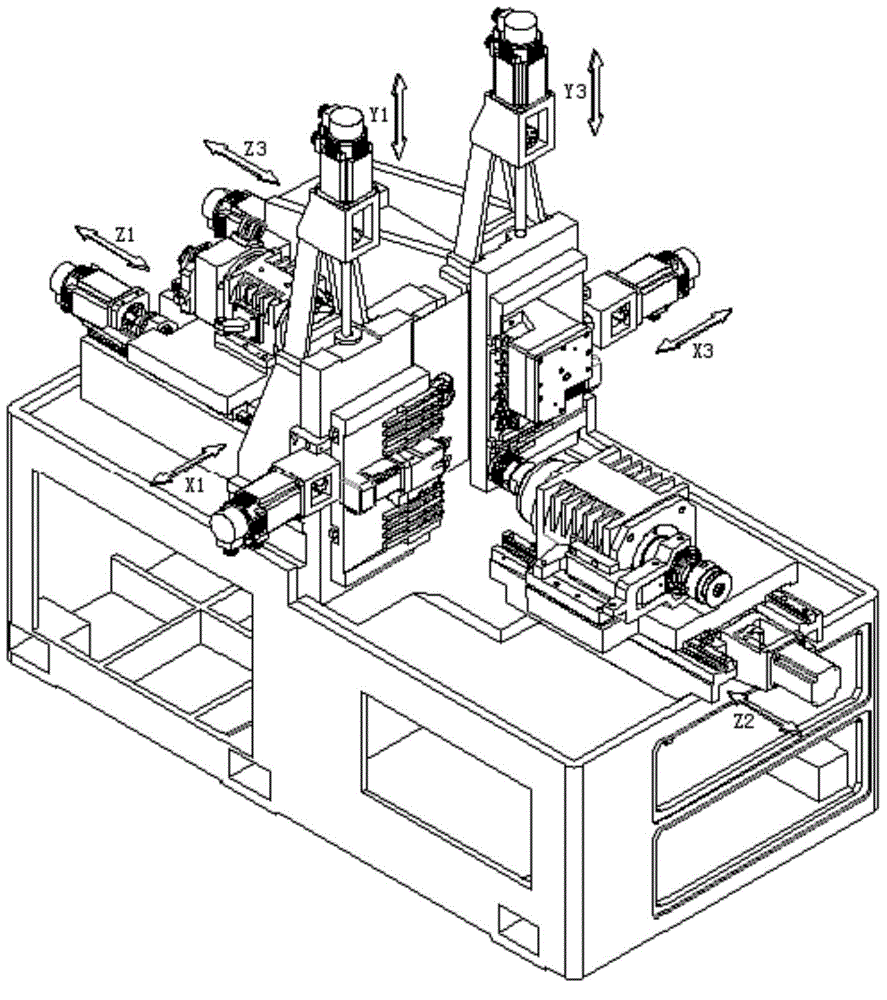

[0062] like figure 1 and figure 2 The shown positive axis includes a six-axis center turning and milling machine tool, including a bed 1, and a column 2 is set on the bed 1 and consists of a first column and a second column arranged along the X-axis direction. The X1 axis The positive axis group consisting of group, Y1 axis group, Z1 axis group and the third axis group composed of X3 axis group, Y3 axis group and Z3 axis group. The second column is provided with a through hole, and a guide sleeve or a structure without a guide sleeve is arranged in the through hole, which can be determined according to actual needs. In the present invention, the upright column can be fixed on the bed with bolts, or can be integrally formed with the bed when manufacturing the bed, and the positive axis group and the third shaft group are arranged side by side along the X-axis direction of the positive axis group. The same end of bed 1.

[0063]The Z1-axis group includes a Z1-axis slide plat...

Embodiment 2

[0075] The difference between the present invention and Embodiment 1 is that the first tool mounting seat 9 is the first turret, the second tool mounting seat 18 is the second turret, and the X1 axis slide block 27 that forms a sliding pair with the X1 axis rail 26 is arranged on the second turret. On the first turret, a tool is installed on the first turret; the X3-axis slider 33 that forms a sliding pair with the X3 axis rail 32 is arranged on the second turret, and a tool is installed on the second turret, and the rest of the structure is the same as that of the embodiment One is the same, see embodiment one for details, and will not be described in detail here.

Embodiment 3

[0077] The difference between this embodiment and Embodiment 1 is that the first tool mounting seat 9 is composed of an X1-axis slide plate and a first turret, and the X1-axis slide block 27 that forms a sliding pair with the Y1-axis rail 26 is installed on the X1-axis slide plate, The first turret is installed on the X3 axis slide plate; the second tool mounting seat 18 is composed of the X3 axis slide plate and the second turret, and the Y3 axis slide block 33 which forms a sliding pair with the X3 axis rail 32 is mounted on the X3 axis slide plate , the second turret is installed on the X3 axis slide plate. Knives are installed on the first turret and the second turret, and the rest of the structure is the same as that of Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com