Recovery method for potassium catalyst in coal catalytic gasification ash

A coal catalytic gasification and recovery method technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high energy consumption and low concentration of potassium recovery solution , low recovery rate of total potassium and other problems, to achieve the effect of reducing concentration energy consumption, overcoming large water consumption, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0071] In the following, the embodiments of the present invention illustrate the technical effects of the present invention through comparative examples and examples respectively. These examples are merely examples for specifically illustrating the present invention, and those skilled in the art will understand that the scope of the present invention is not limited by these examples, comparative examples, and test examples.

Embodiment 1

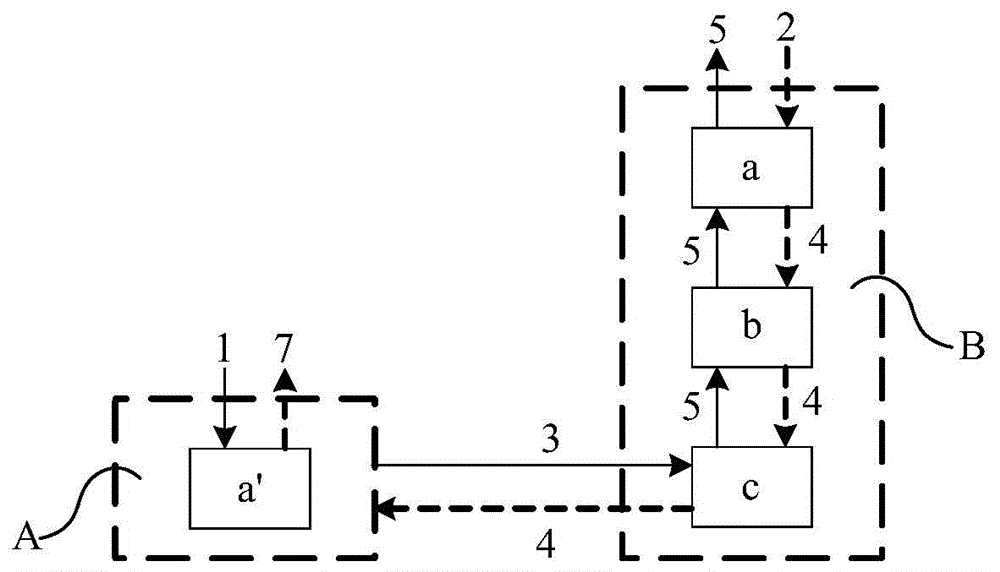

[0077] see figure 2 , the water washing section of Example 1 includes a first-stage water washing process, and the digestion section includes a fourth-stage digestion reaction.

[0078] Specifically, the washing process of the washing section A is as follows: the coal catalytic gasification ash 1 enters the washing section A for washing, the washing temperature is 80°C, and the washing is stirred and washed for 1 hour, wherein the washing liquid 6 in the washing section A is The digestion potassium solution 4 from the digestion section B, the water washing solution 6 washes the coal catalytic gasification ash 1 and then outputs the potassium solution 7 and the washing slag 3, and the washing slag 3 enters the last stage of digestion reaction d The reactor is used as the raw material for the final digestion reaction d.

[0079] The digestion reaction of the specific digestion section B is: add digestion solution 2 in the reactor of the first-level digestion reaction a, and th...

Embodiment 2

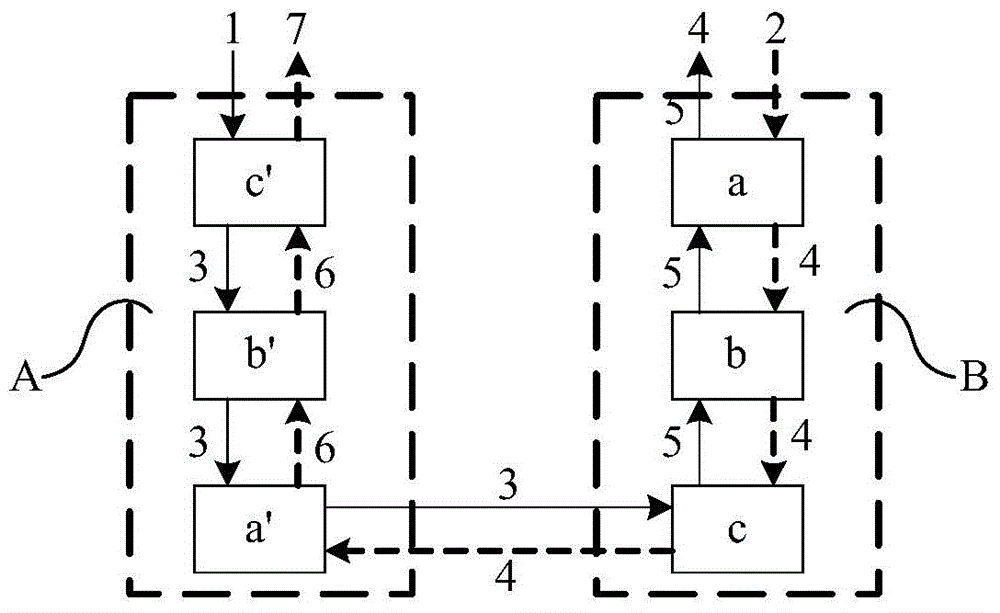

[0082] see Figure 5 , the water washing section of Example 2 includes a 4-stage water washing process, and the digestion section includes a 1-stage digestion reaction.

[0083] Specifically, the washing process of the washing section A is as follows: the washing temperature of each washing process reactor in the washing section is 60°C, the washing time is 2h, and the coal catalytic gasification ash 1 enters the final washing process d' The reactor is washed with the water washing solution 6 in the reactor from the previous water washing process c', and the reactor in the last water washing process d' outputs the potassium solution 7, and the water washing slag 3 enters the The reactor of the upper-level water washing process c' is washed with the washing liquid 6 from the reactor of the adjacent upper-level water washing process b' to obtain the water-washing slag 3 and then enter the upper-level water washing process b ', and so on, after four stages of water washing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com