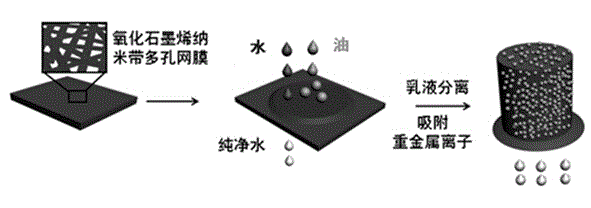

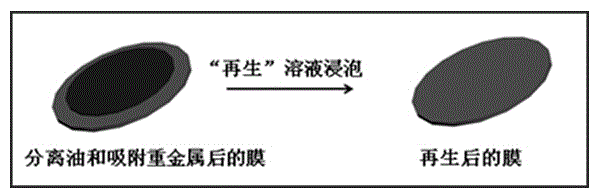

Preparation method of multifunctional oil-water separation material based on graphene oxide nanobelt

A technology of graphene nanoribbons and separation materials, which is applied in the field of preparation of hierarchical porous composite meshes, can solve problems such as inability to separate metal ions, and achieve the effects of self-cleaning, controllable parameters, and good adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment 1: In this embodiment, a multifunctional oil-water separation material is prepared according to the following steps:

[0033] 1. Cutting functionalized graphene oxide nanoribbons by oxidation method:

[0034] (1) Measure 2-50mL of phosphoric acid solution into a 500mL round bottom flask, add 20-400mL of concentrated sulfuric acid, and stir evenly at a speed of 15000-30000rpm;

[0035] (2) Weigh 0.1-10g of carbon nanotubes into the mixed acid solution in step (1), and stir for 0.1-5h;

[0036] (3) Slowly add 0.1-50g of potassium permanganate into the mixture in step (2) in 3 steps, and stir for 0.5-1h;

[0037] (4) Move the above reaction system to an oil bath at 30-70°C, stir and react at a speed of 15000-30000rpm for 5-48h, then cool down to room temperature;

[0038] (5) Pour the solution in step (4) into the ice-water mixture containing 2-50mL hydrogen peroxide (30%) to condense for 5-48 hours. At this time, the solution turns dark green, indica...

specific Embodiment approach 2

[0048] Specific embodiment two: In this embodiment, a multifunctional oil-water separation membrane is prepared according to the following steps:

[0049] 1. Cutting functionalized graphene oxide nanoribbons by oxidation method;

[0050] (1) Measure 20mL of phosphoric acid solution into a 500mL round bottom flask, then add 180mL of concentrated sulfuric acid and stir evenly at a speed of 30000rpm;

[0051] (2) Weigh 1g of carbon nanotubes into the above mixed acid solution and stir for 1h;

[0052] (3) Slowly add 6g of potassium permanganate into the above mixture in 3 steps and stir for 30min;

[0053] (4) Move the above reaction system to an oil bath at 45°C, stir and react at a speed of 30,000 rpm for 24 hours, then cool down to room temperature;

[0054] (5) Pour into an ice-water mixture containing 10mL hydrogen peroxide (30%) and condense for 24 hours. At this time, the solution turns dark green, indicating that the reaction is complete;

[0055] (6) Add 100mL of 10% ...

specific Embodiment approach 3

[0064] Specific embodiment three: In this embodiment, a multifunctional oil-water separation membrane is prepared according to the following steps:

[0065] 1. Cutting functionalized graphene oxide nanoribbons by oxidation method:

[0066] (1) Measure 20mL of phosphoric acid solution into a 500mL round bottom flask, then add 180mL of concentrated sulfuric acid and stir evenly at a speed of 30000rpm;

[0067] (2) Weigh 3g of carbon nanotubes into the above mixed acid solution and stir for 1 hour;

[0068] (3) Slowly add 6g of potassium permanganate into the above mixture in 3 steps and stir for 30min;

[0069] (4) Move the above reaction system to an oil bath at 45°C, stir and react at a speed of 30,000 rpm for 24 hours, then cool down to room temperature;

[0070] (5) Pour into an ice-water mixture containing 10mL hydrogen peroxide (30%) and condense for 24 hours. At this time, the solution turns dark green, indicating that the reaction is complete;

[0071] (6) Add 100mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com