Separator-plates alternative extraction tower and extraction method

An extraction tower and alternating technology, which is applied in the partition alternating extraction tower and the field of extraction, can solve the problems of wide variation range of continuous phase and dispersed phase fluid concentration, large difference in liquid-liquid two-phase flow ratio, etc., to improve the overall transmission Massive driving force, increased flow and average flow rate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

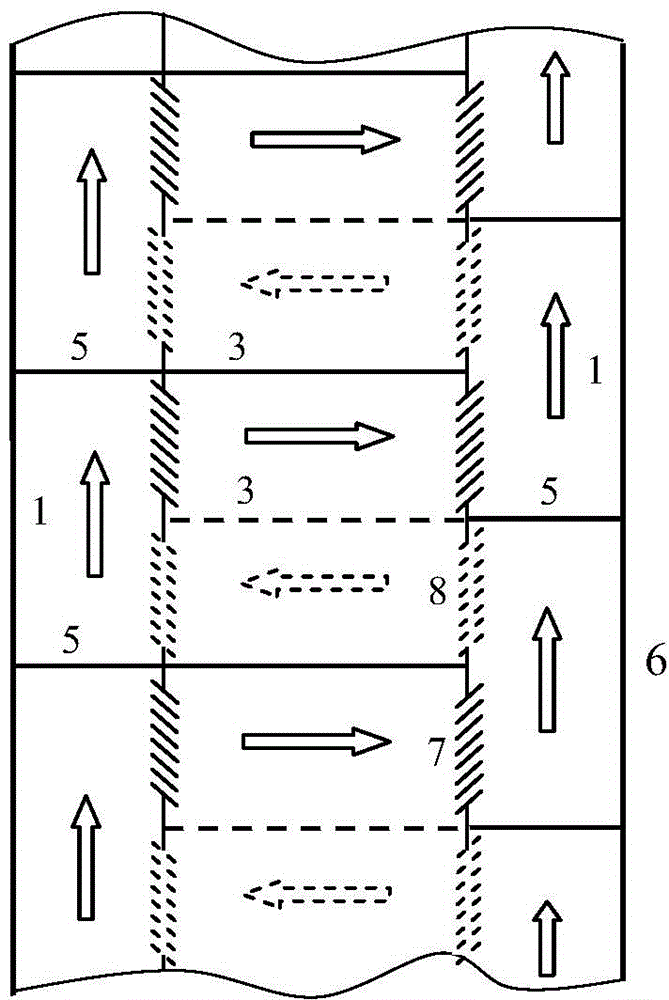

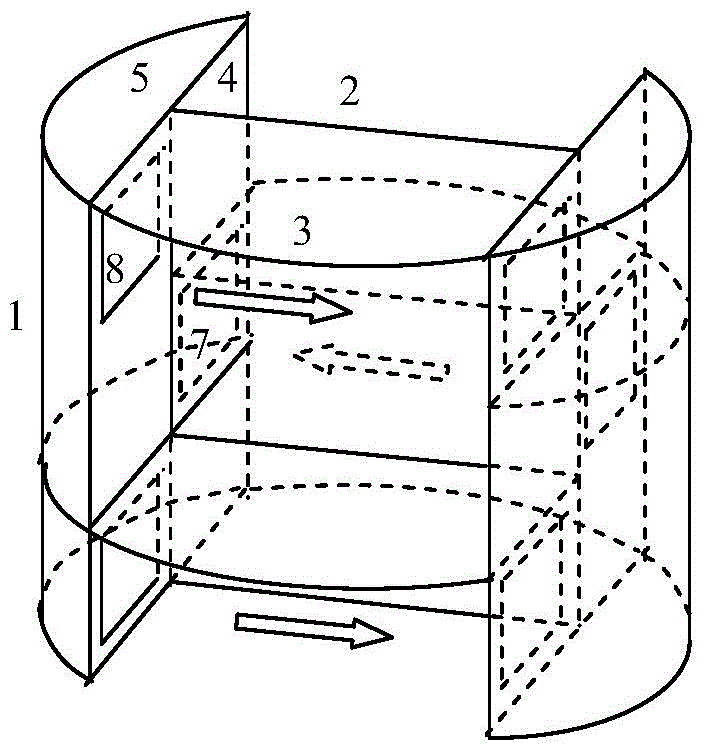

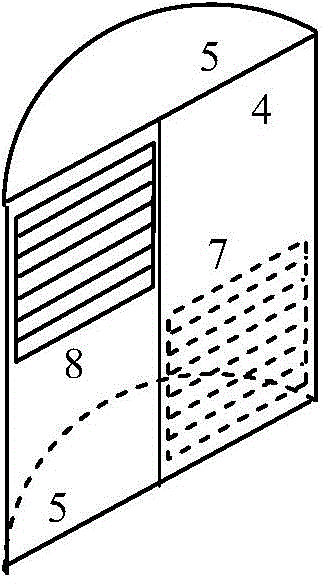

[0024] Such as Figure 1-5 As shown, an alternate partition extraction tower of the present invention includes two arcuate riser pipes 1 placed opposite each other, and a vertical intermediate partition 2 is welded on the central axis of the two arcuate riser pipes 1. 2 Divide the space in the circular extraction tower into two mass transfer zones.

[0025] Semicircular trays 3 are alternately arranged on both sides of the intermediate partition 2 at equal intervals. The tray 3 on one side is just in the middle of the two trays 3 on the other side. The tray 3 is a sieve plate or a perforated plate, on the same side. A mass transfer unit is formed between two adjacent semicircular trays 3; by staggering the trays 3, continuous and same flow flow between adjacent trays 3 on the same side of the partition 2 can be realized, which is adjacent to the tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com