A kind of preparation method of Eucommia gum gum base

A technology of chewing gum base and eucommia gum, applied in chewing gum, food science, application, etc., can solve the problems of high hardness and unfavorable chewing, and achieve the effects of operation, environmental pollution reduction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

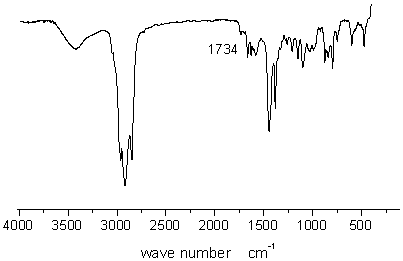

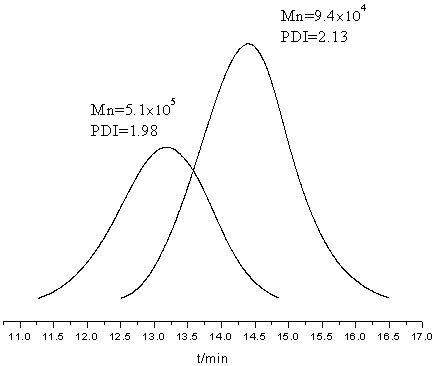

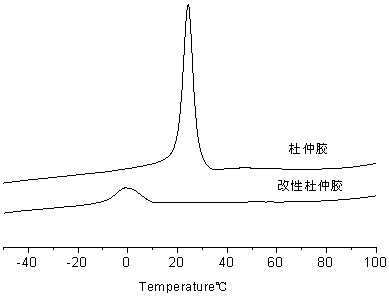

Image

Examples

Embodiment 1

[0022] Add 7 ml of deionized water to 3 g of Eucommia gum to prepare a suspension. Pour the suspension into a pulverizer and mechanically pulverize at room temperature for 1 min. The product was filtered and dried to obtain eucommia gum particles. The obtained eucommia gum granules, 200 ml of deionized water and 0.15 g of talc powder were added into a three-necked flask, and the temperature was raised to 70° C. and mechanically stirred for 1.5 h. Add 0.15 g of potassium persulfate to the three-necked flask, react for 8 h, and take out the product by suction filtration. After washing and drying, the modified Eucommia gum was obtained.

Embodiment 2

[0024] Add 15 ml of deionized water to 5 g of Eucommia gum to prepare a suspension. The suspension was poured into a pulverizer, and mechanically pulverized at room temperature for 1.5 min. The product was filtered and dried to obtain eucommia gum particles. The obtained eucommia gum granules, 300 ml of deionized water and 0.2 g of talc powder were added into a three-necked flask, and the temperature was raised to 80° C. and mechanically stirred for 1.5 h. Add 0.15 g of potassium persulfate to the three-necked flask, react for 3 h, and take out the product by suction filtration. After washing and drying, the modified Eucommia gum was obtained.

Embodiment 3

[0026] Add 5 ml of deionized water to 3 g of Eucommia gum to prepare a suspension. Pour the suspension into a pulverizer and mechanically pulverize at room temperature for 1 min. The product was filtered and dried to obtain eucommia gum particles. The obtained eucommia gum granules, 150 ml of deionized water and 0.1 g of calcium carbonate were added into a three-necked flask, and the temperature was raised to 40° C. and mechanically stirred for 2 h. Add 0.15 g of potassium persulfate and 10% H to the three-neck flask 2 o 2 0.2 ml, reacted for 3 h and filtered out the product. After washing and drying, the modified Eucommia gum was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com