Suction roll system

A control system, low-voltage system technology, applied in the direction of textile and paper making, paper machine, object supply, etc., can solve the problem of unfavorable length and cross-section ratio, and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

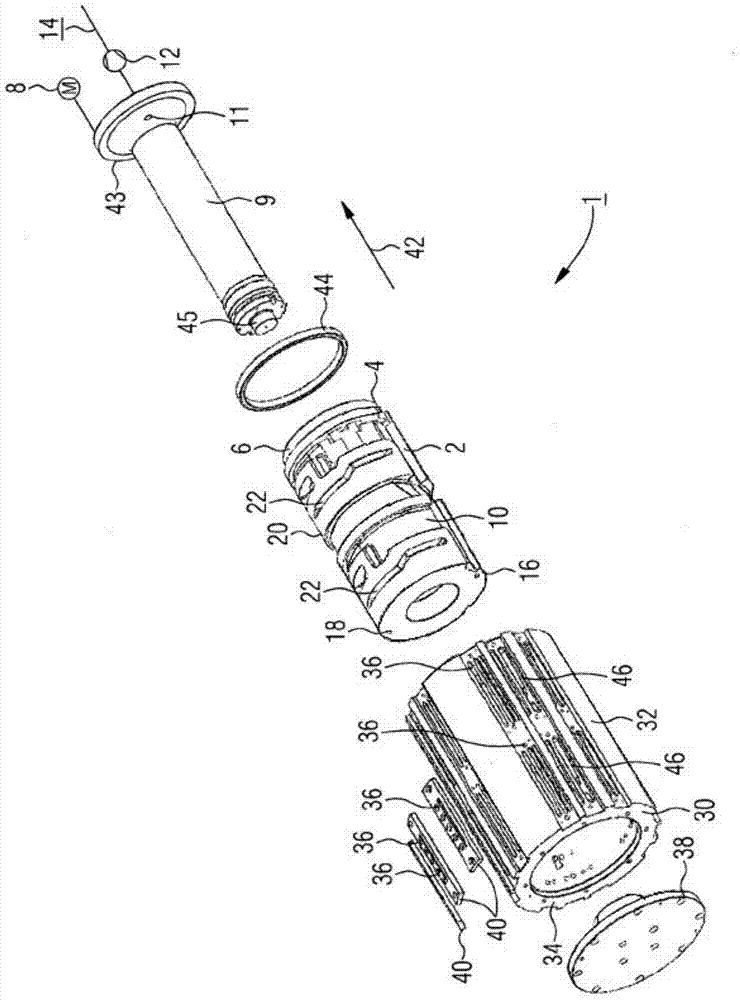

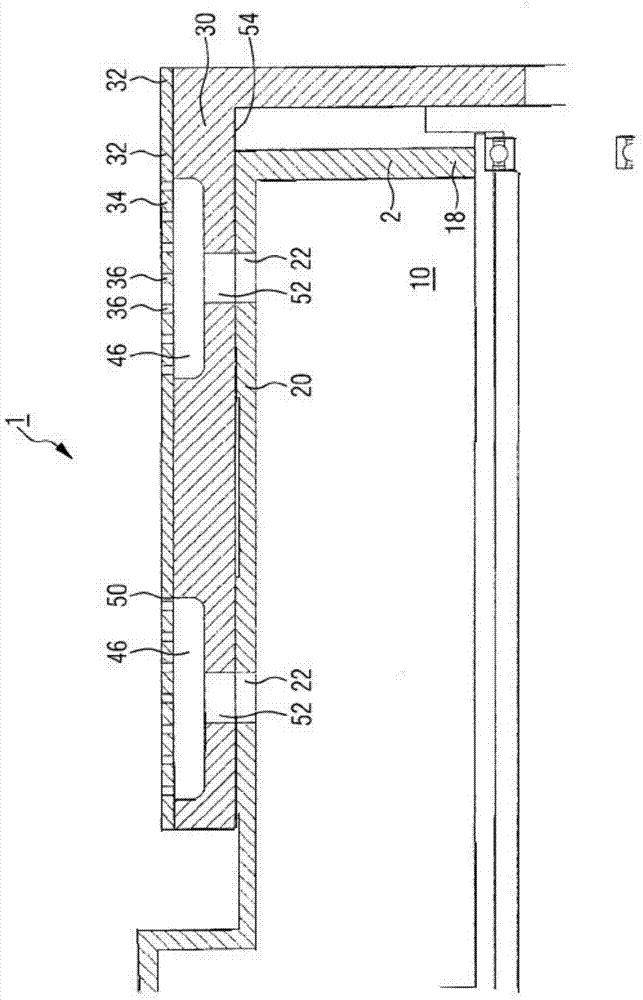

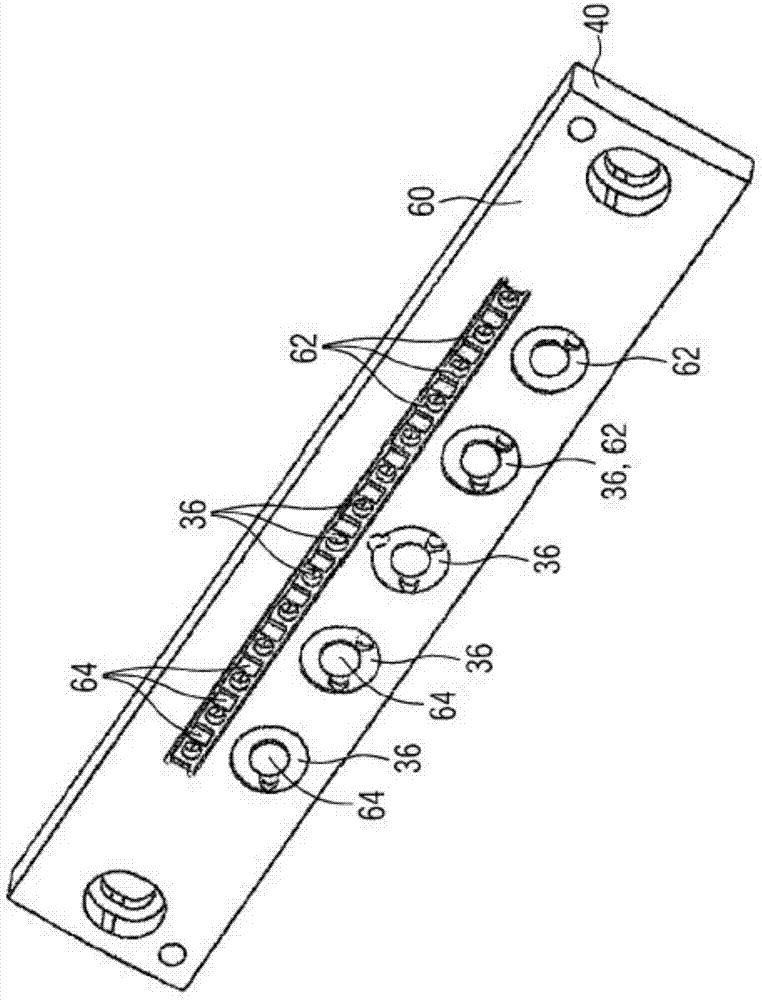

[0029] according to figure 1 The suction roll system is arranged to be used in a device not shown in detail for processing paper or cellulose webs. In this device, the paper web or cellulose web is first guided as a whole by functional rollers (for example deflection rollers, but also cutting or separating rollers). Depending on the intended use of the device, the material web is here cut into a plurality of individual planar pieces (for example paper pieces) or cellulose pieces (for example handkerchiefs or similar objects), which are subsequently conveyed or supplied individually to another a processing position. While the individual blocks are being conveyed further, they can also be deflected, supported or processed, such as punching out windows in the form of other cutting processes, making impressions or the like.

[0030] The suction roll system 1 can be used at any position in the device as individual function rollers or function rolls, and the suction roll system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com