Light guide plate and backlight module

A technology of light guide plate and light guide part, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of excessive loss of light, reduce light utilization rate, and difficulty in achieving light coupling efficiency, so as to improve light coupling efficiency and benefit Thin design, the effect of improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

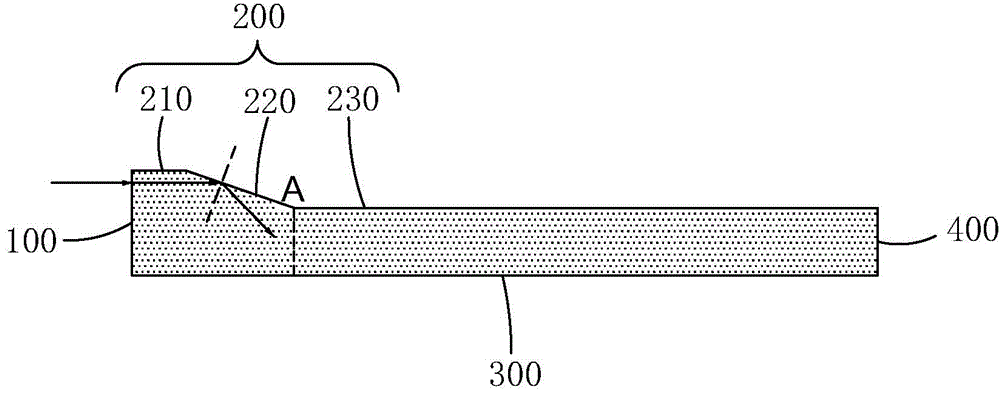

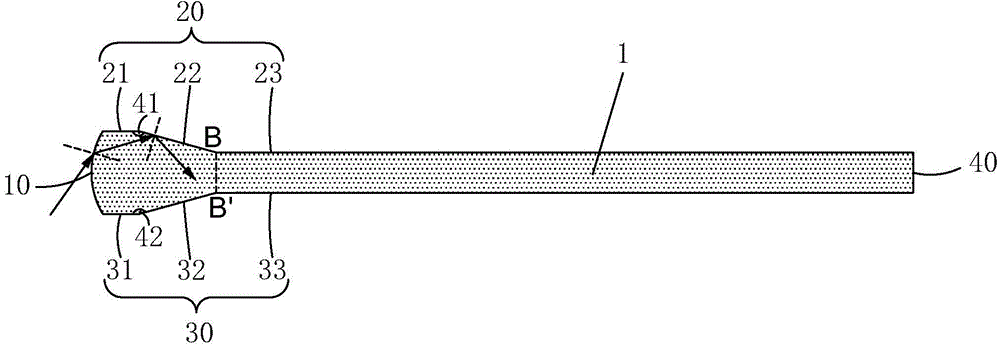

[0032] See image 3 , The present invention provides a light guide plate 1, which has a first end surface 10, a second end surface 40 corresponding to the first end surface 10, and an upper surface connecting the upper ends of the first end surface 10 and the second end surface 40 respectively 20. And the lower surface 30 respectively connecting the lower ends of the first end surface 10 and the second end surface 40;

[0033] Specifically, the upper surface 20 is composed of three parts, namely a first horizontal plane 21, a first inclined plane 22, and a second horizontal plane 23; the first horizontal plane 21 is connected to the first end surface 10, and the first inclined plane 22 is connected at an inclination between the first horizontal plane 21 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com