High-level and high-rise structure dynamic detection bearing capacity evaluating method

A bearing capacity and dynamic detection technology, applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve the problems of limiting the application of dynamic evaluation methods, application limitations, etc., to achieve strong operability and guiding significance, suitable for Wide-ranging, less time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] In the figure, a method for evaluating the load-carrying capacity of high-rise and high-rise structures according to the present invention is based on dynamic detection technology, combined with parameter identification method and finite element correction technology to realize the load-carrying capacity evaluation of high-rise and high-rise structures, including the following steps:

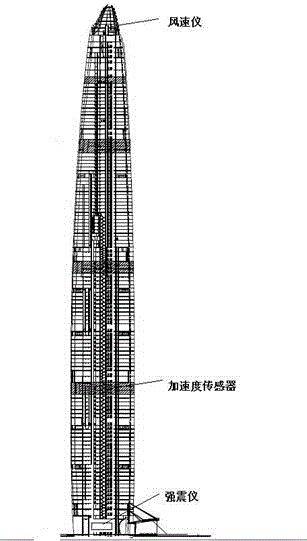

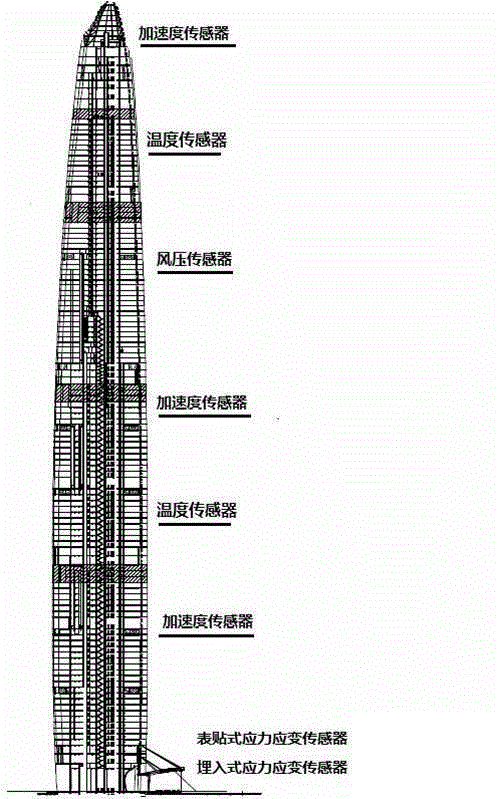

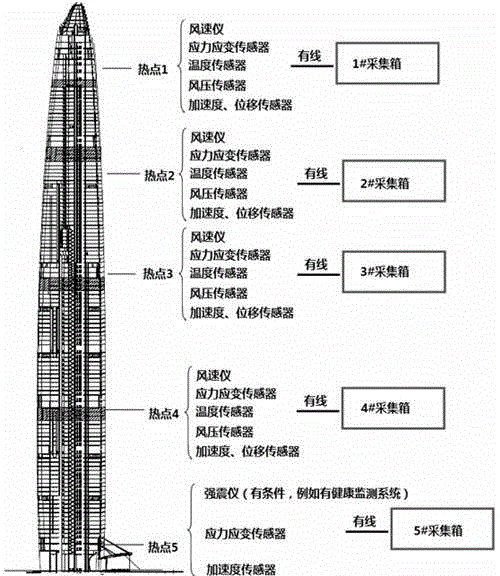

[0025] Step 1 Design status of high-rise and high-rise structures, conduct model correction finite element analysis according to the construction acceptance data, preliminarily determine the mode parameters and frequency parameters of high-rise and high-rise structures, and preliminarily determine the significant mode response area and force of high-rise and high-rise structures Deformation hotspots;

[0026] Step 2. Dynamic input vibration pickup settings for high-rise and high-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com