Pneumatic sensor

A pneumatic sensor and sensor unit technology, applied in the field of sensors, can solve the problems of being susceptible to external vibration interference, high requirements for external signal processing circuits, and small output signals, and achieve low production costs, low requirements, and large output signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

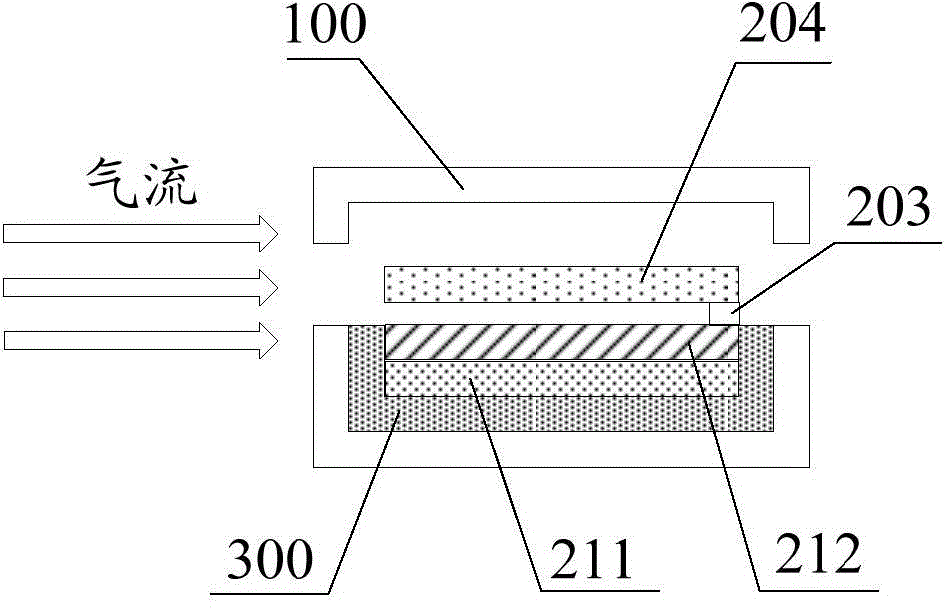

[0059] The present invention provides a pneumatic sensor, which comprises: a shielding shell, an insulating layer arranged on part or all of the inner surface of the shielding shell, and at least one sensing unit. At least two air vents are opened on the shielding shell, and the air flow passes between the air vents. The sensing unit includes: at least one fixed layer and one free layer. At least one fixed layer is fixed on the shielding shell. The free layer has a fixed part and a friction part, the fixed part of the free layer is fixedly connected with at least one fixed layer or the shielding shell, and the free layer rubs against at least one fixed layer and / or the shielding shell through the friction part. Wherein, at least one fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com