Deviation Correction Method for Angle Scale of Large Jigsaw Board

A technology of angular scale and jigsaw panels, which is applied in the field of splicing, positioning, and deviation correction of large jigsaw panels. It can solve problems such as difficult operation, large error of deviation correction methods, and diamond-shaped steel plates, etc., to achieve simple operation, avoid rework, and simple and easy-to-understand deviation correction methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

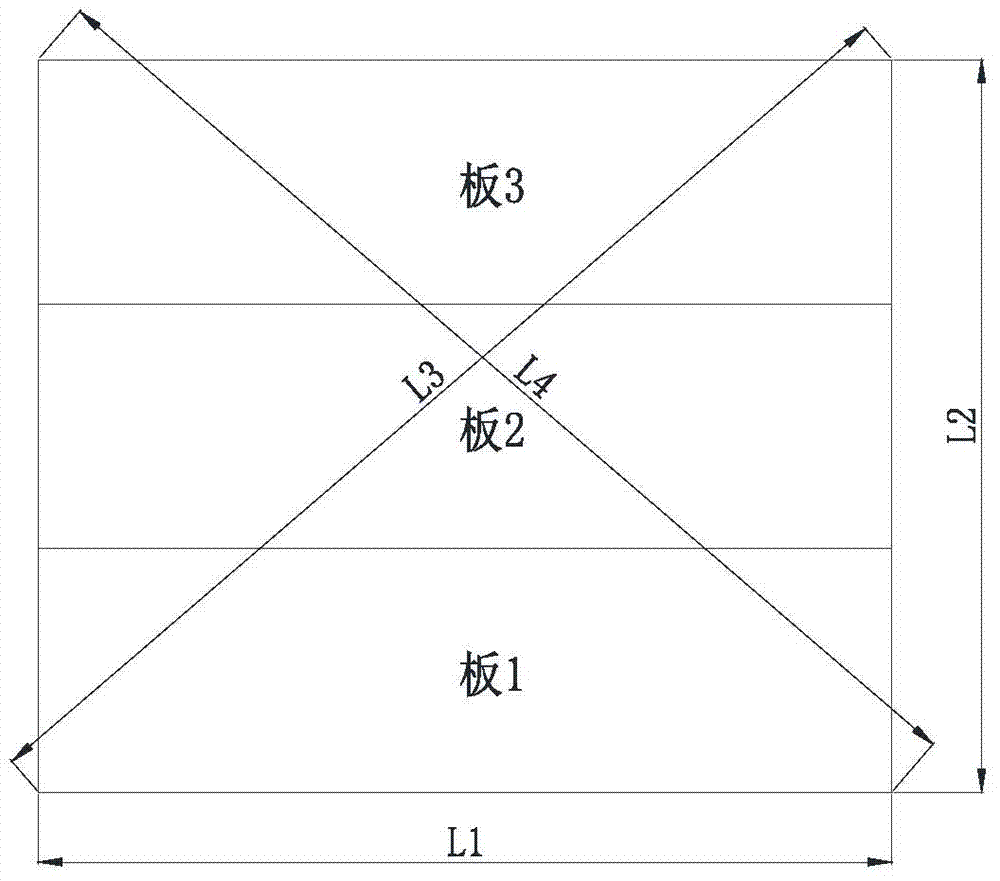

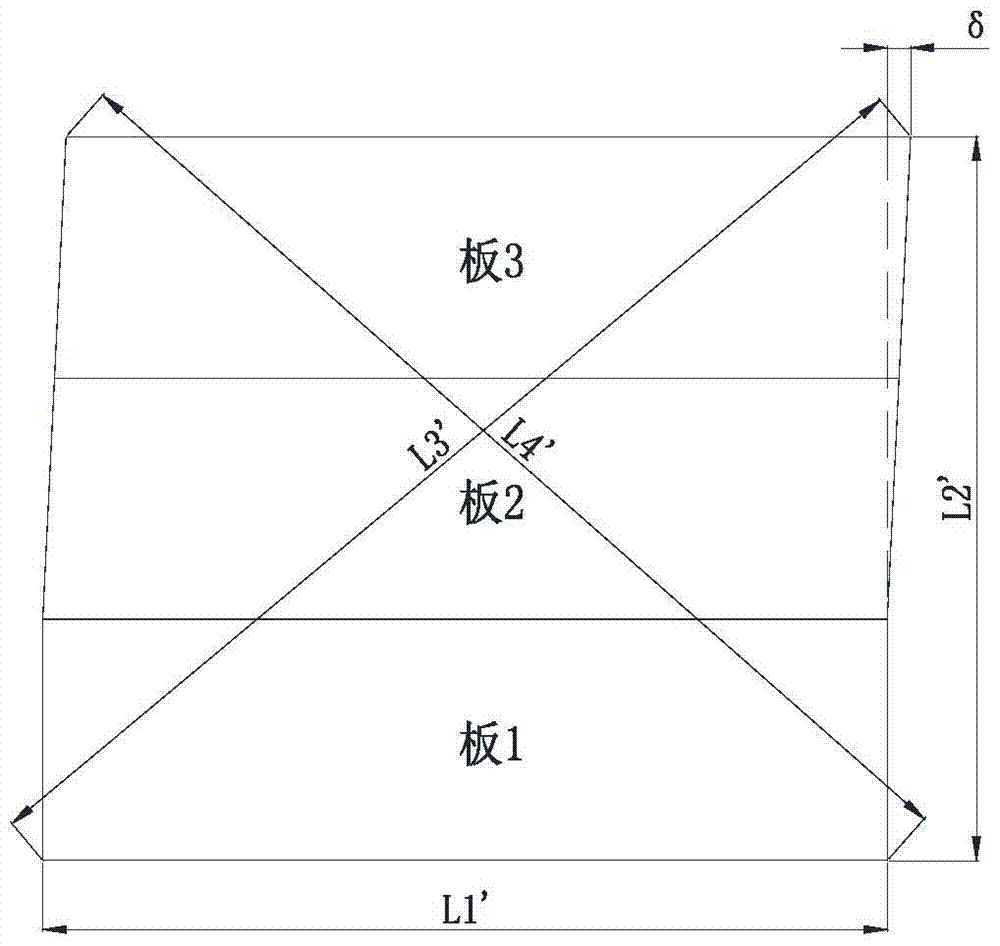

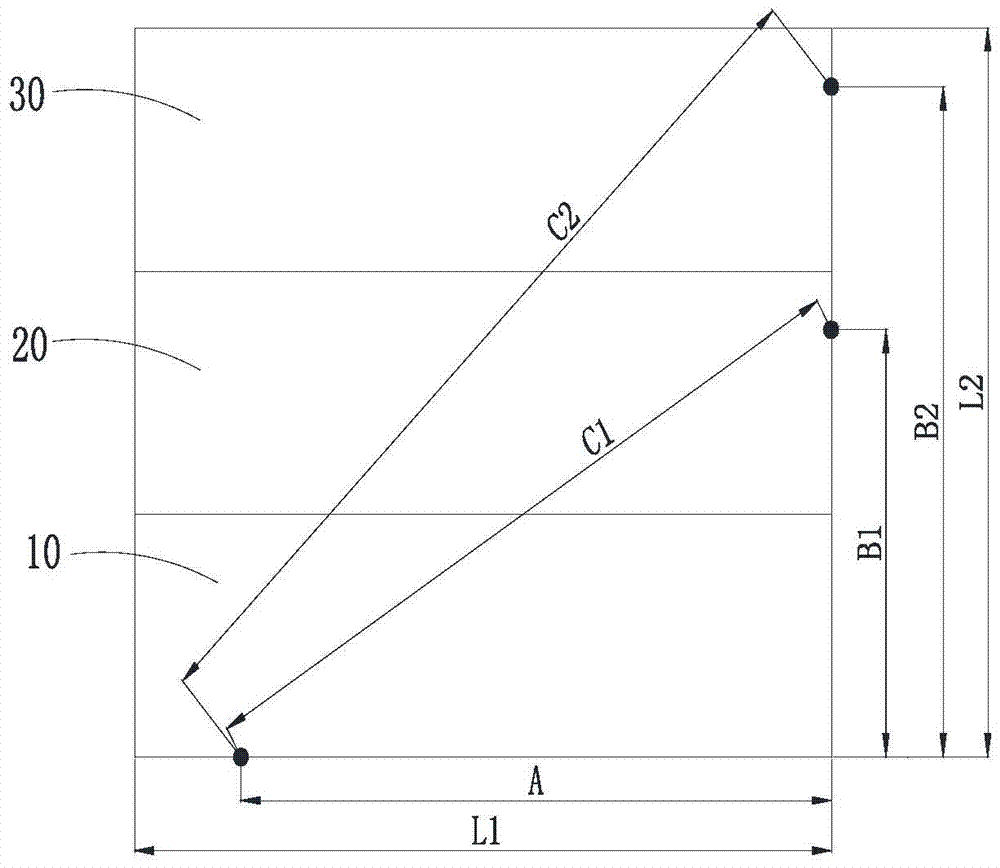

[0027] see Figure 3 to Figure 5 , the present invention relates to a deviation correction method for the angular scale of a large jigsaw puzzle, the deviation correction method comprising:

[0028] In step S1, the plates to be spliced and the base material are aligned and placed side by side; in this embodiment, the first steel plate 10 is first set as the base material, and the second steel plate 20 is the plate to be spliced; the plates to be spliced and the base material are also Other boards are possible.

[0029] Step S2, take the free long si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com