Oil removal cooling compressor

An oil cooling and air compressor technology, applied in the field of gas compression, can solve the problems of reducing the purity of compressed gas, the high risk of high-temperature gas, and the temperature rise of compressed gas, etc., and achieve reasonable structural design, low subjective dependence, and working accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

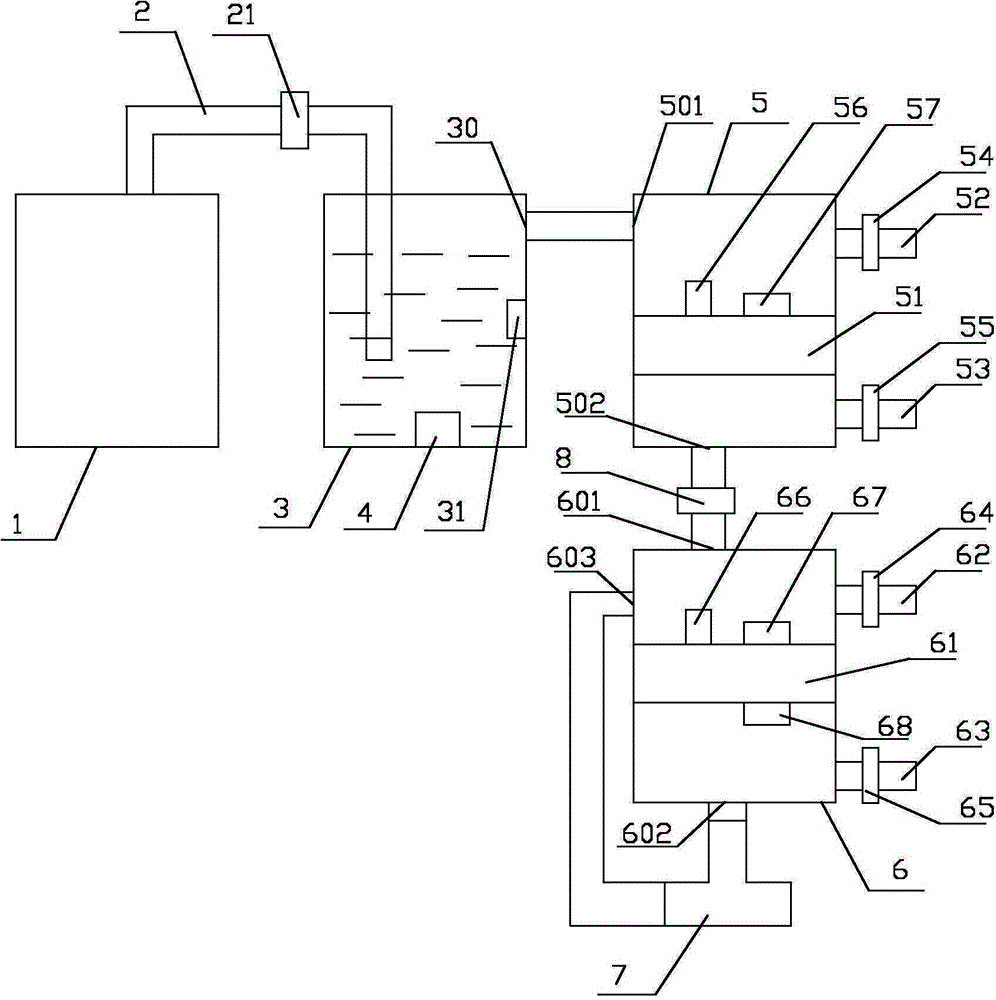

[0027] refer to figure 1 , a kind of deoiling cooling air compressor that the present invention proposes, comprises: cylinder 1, air supply pipeline 2, liquid storage tank 3, refrigeration device 4, first dehumidification box 5, second dehumidification box 6, three-way valve 7 and control module.

[0028] A gas compression device is arranged in the cylinder 1 for compressing gas. Cooling liquid is stored in the liquid storage tank 3, specifically, cooling water can be used. The refrigerating device 4 is installed in the liquid storage tank 3 and is located below the liquid surface for compensating the cooling capacity of the cooling liquid. The first end of the air supply pipe 2 is connected to the outlet of the cylinder 1, and the second end is inserted into the liquid storage tank 3 and is located below the liquid level. The liquid storage tank 3 is provided with an air outlet 301 and is located above the liquid level. The compressed gas output by the cylinder 1 enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com