Energy-saving regulating and controlling method for combustion fan of blast furnace hot blast stove

A technology of combustion-supporting fan and hot blast stove, which can be applied to blast furnace details, blast furnaces, blast furnace parts, etc., and can solve problems such as waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

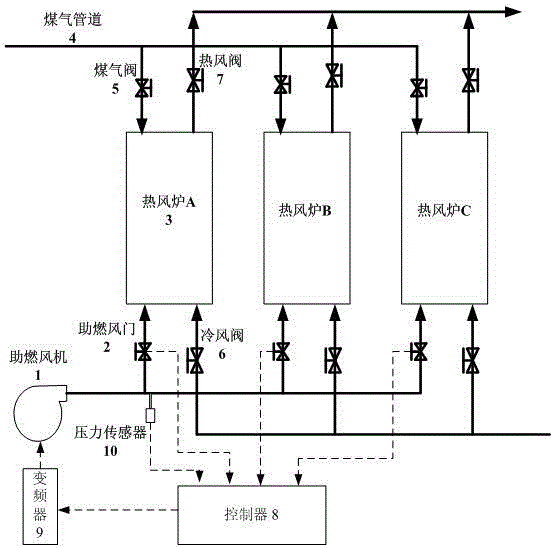

[0016] Embodiment 1: The energy-saving control mode of a kind of blast furnace hot stove combustion-supporting fan of the present invention is as follows figure 1 As shown, when the present invention is implemented without changing the operating conditions of the combustion-supporting blower of the original blast furnace hot blast stove, a pressure sensor 10 is installed on the outlet pipe of the combustion-supporting blower, and a frequency converter 9 is installed on the combustion-supporting blower 1. The opening signal of the combustion-supporting air door 2 of each hot blast stove, the control signal of the frequency converter 9 , and the pressure signal of the pressure sensor 10 are all connected to the energy-saving controller 8 . The invention adopts the pressure adjustment technology under the linkage of the air door to adjust and control the air supply process of the combustion-supporting fan, so as to achieve the purpose of greatly saving energy and reducing consumpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com