Ring Lime Shaft Kiln

A lime and shaft kiln technology, applied in lime production and other directions, can solve the problems of energy saving, calcination uniformity and efficiency to be improved, etc., and achieve the effects of convenient multi-faceted calcination, safe operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

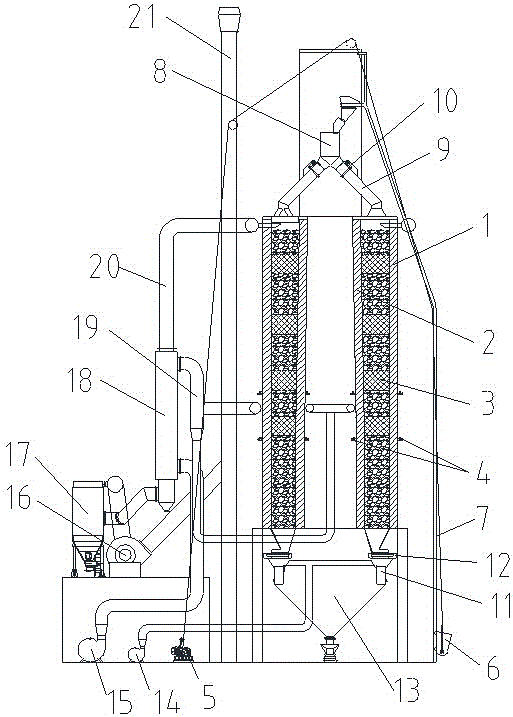

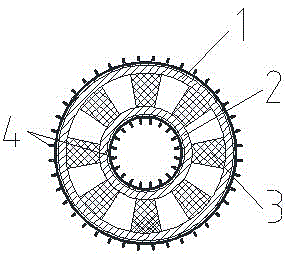

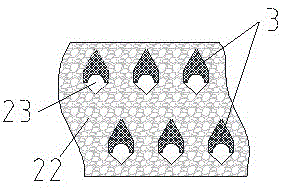

[0024] figure 1 The overall structure of the gas calcined annular lime shaft kiln of the present invention is provided, mainly including the kiln body, and the cross-sectional structure of the kiln body is as follows: figure 2 shown. The kiln body is composed of an outer ring wall 1 and an inner ring wall 2. The inner ring wall 2 is set inside the outer ring wall 1, and an annular cavity is formed between the two. In the annular cavity, a connecting outer ring wall is arranged from top to bottom. 1 and the multi-layer (2-6 layers) lintel 3 of the inner ring wall 2, the material (limestone) falls and resides in the annular cavity with the lintel. The arrangement of the lintel 3 is as follows image 3 As shown, the structure of the lintel 3 is as Figure 4 As shown, there is a cavity at the bottom. Both the inner wall of the outer ring wall 1 and the outer wall of the inner ring wall 2 are provided with refractory linings. The annular cavity is divided into a preheating zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com