Barrel bag opening device

A barrel bag and base technology, which is applied in the field of barrel bag opening devices, can solve the problems of high manufacturing cost, low bag opening efficiency, troublesome adjustment, overhaul and maintenance, etc., and achieves the solution of labor recruitment difficulties, high product quality, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

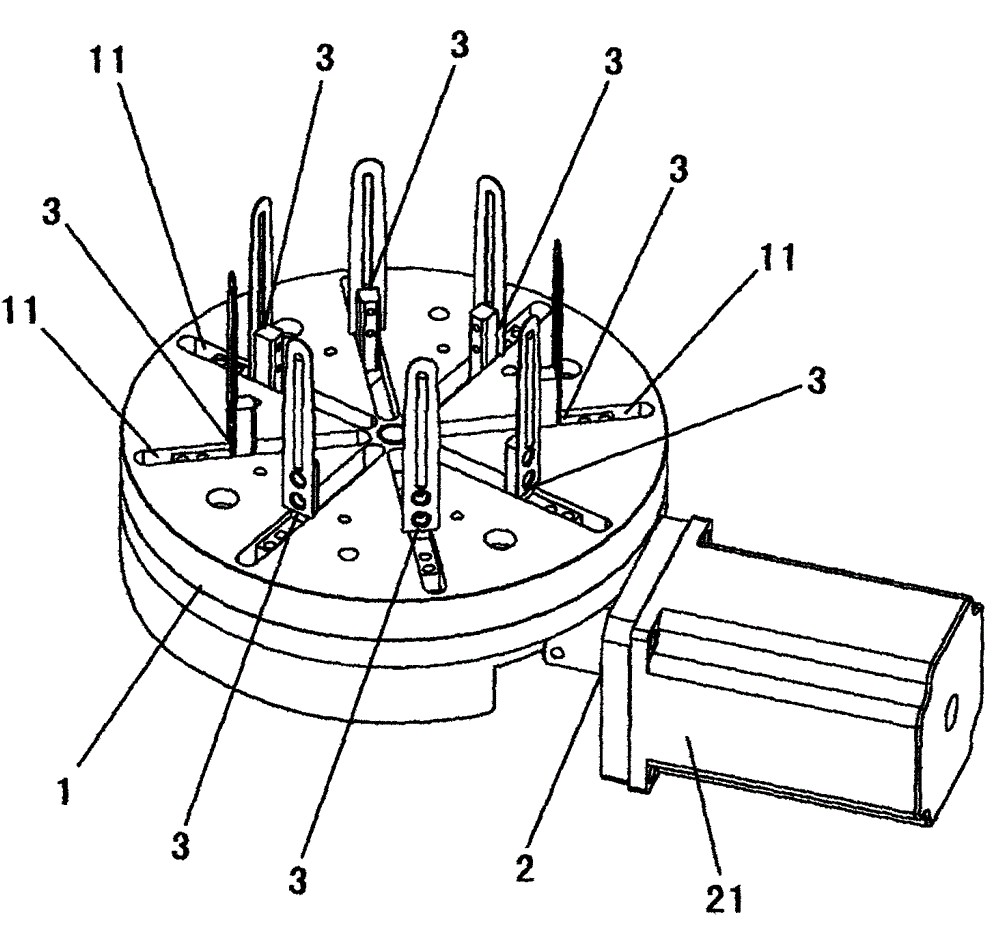

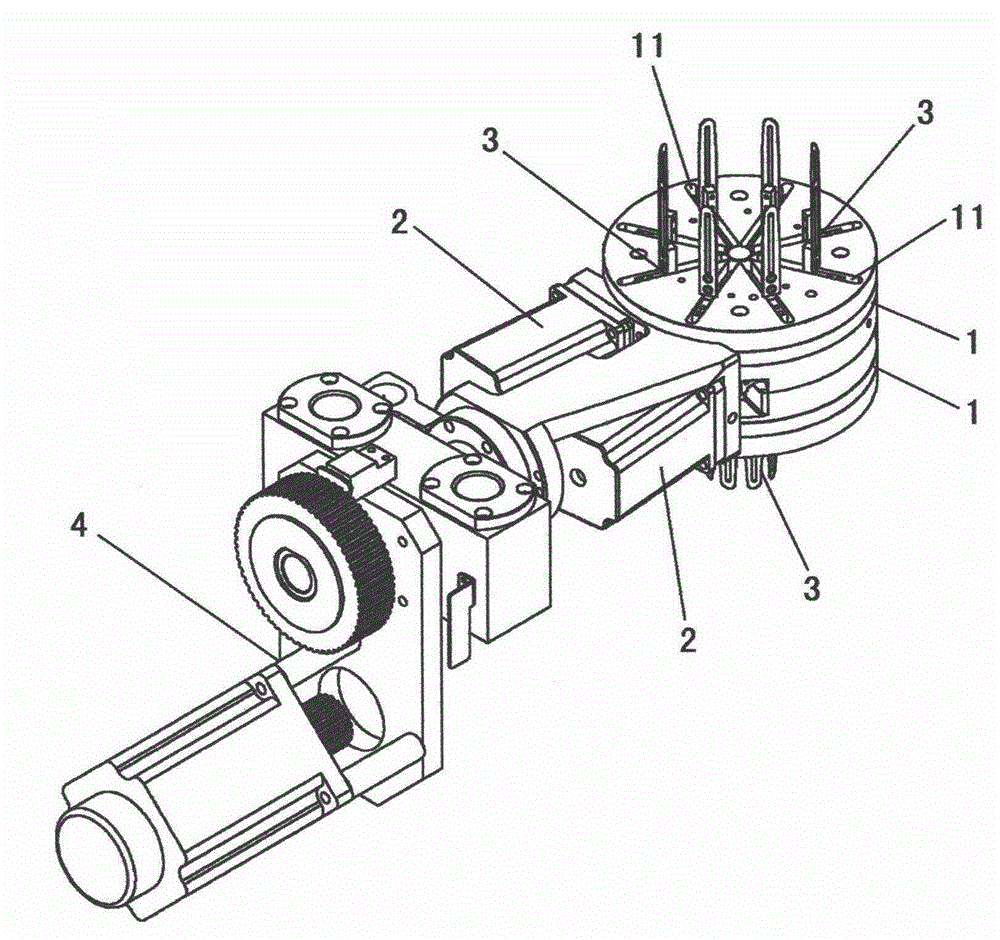

[0016] Such as Figure 1-2 As shown, the tube bag stretching device in the embodiment of the present invention includes a base 1, a driving mechanism 2 and a bag stretching mechanism 3. In this embodiment, the stretching of a cylindrical bag body is taken as an example, and the bag stretching mechanism 3 is set to eight group; the drive mechanism 2 includes a two-way drive motor 21, a worm 22, a turbine 23, and a driving gear 24, the worm 22 is connected to the power input end of the two-way drive motor 21, and the worm 22 meshes with the worm 23, The driving gear 24 is rotatably installed on the base 1, and the worm gear 23 drives the driving gear 24 to rotate through the central transmission shaft; the eight groups of bag supporting mechanisms 3 all include a bag supporting part 31, a rack 32, a driven Gear 33, the bag holder 31 is fixed on the rack 32, the driven gear 33 is rotatably installed on the base 1, the rack 32 is meshed with the driven gear 33, the driving gear 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com