Single corrugated board production device

A corrugated cardboard and production device technology, applied in the direction of machining/deformation, can solve the problems of shortened pressure bonding time, tearing of core paper, and larger device size, so as to achieve the effect of easy repair work and high production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

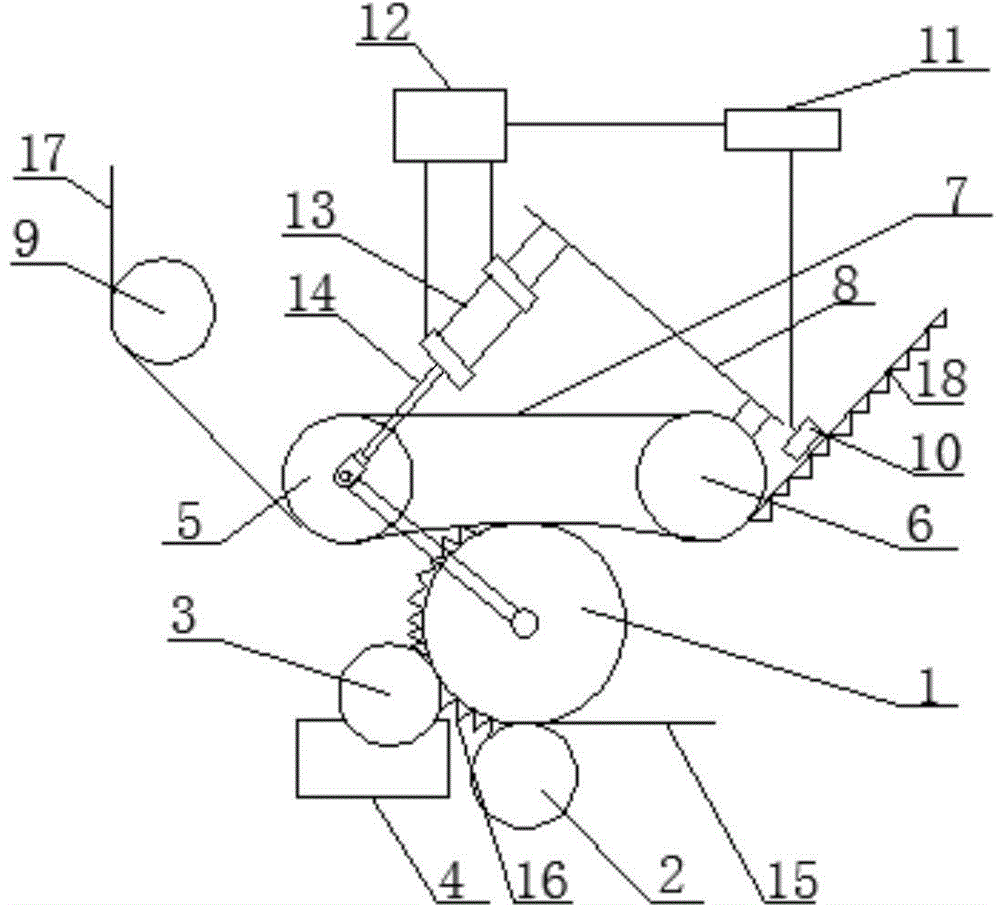

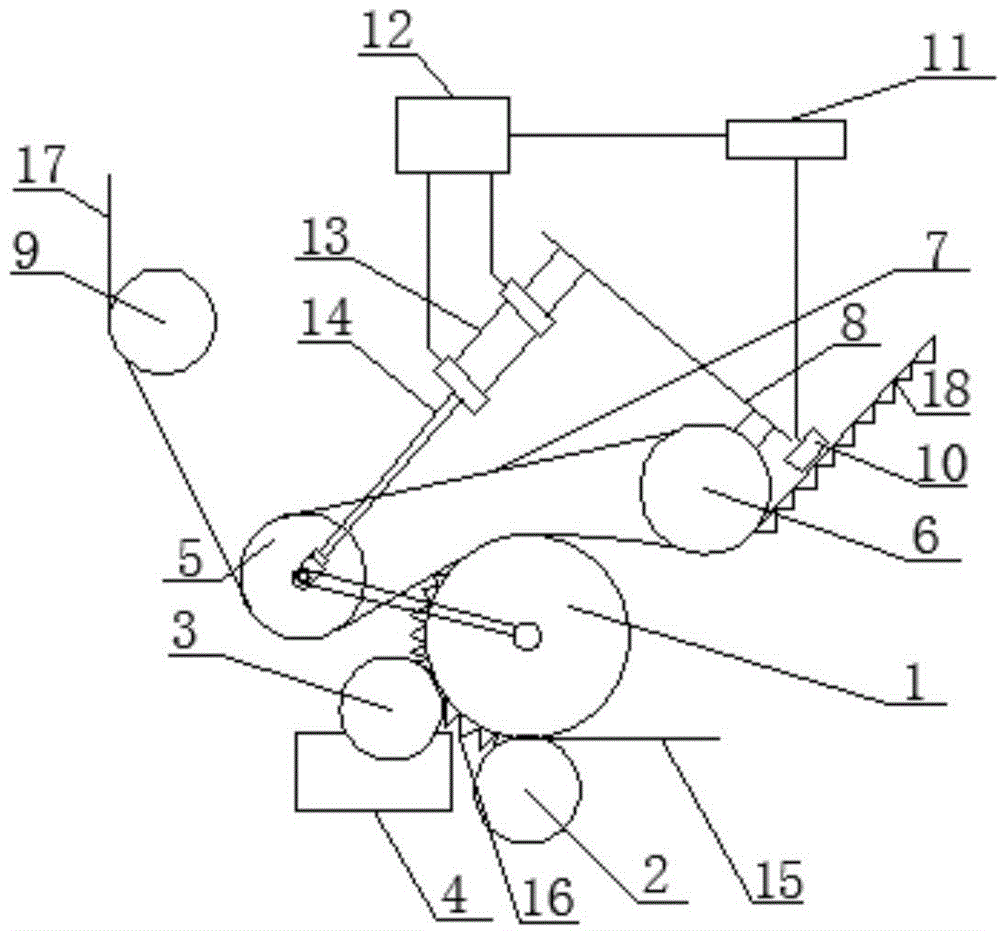

[0024] Such as figure 1 , 2 As shown, a single-face corrugated cardboard production device includes a corrugated core cardboard forming device, a gluing device, a liner cardboard conveying device 9, a forming device, a temperature control device and a driving device;

[0025] The corrugated core cardboard forming device includes an upper corrugating roller 1 and a lower corrugating roller 2 arranged in parallel up and down. The upper corrugating roller 1 and the lower corrugating roller 2 mesh with each other. The pitch circle diameter of the upper corrugating roller 1 is larger than that of the lower corrugating roller 2. And the ratio of the pitch circle diameter of the upper corrugating roll 1 to the pitch circle diameter of the lower corrugating roll 2 is 2:1;

[0026] The gluing device includes a gluing roller 3, the gluing roller 3 meshes with the upper corrugating roller 1, and a glue storage tank 4 is arranged under the gluing roller 3;

[0027] The forming device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com