Board return device and return method

A technology of wire return device and plate parts, which is applied in the field of assembly, can solve the problems that the front and back marking of large-width steel plates cannot be completed, and achieve the effect of increasing width and length and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

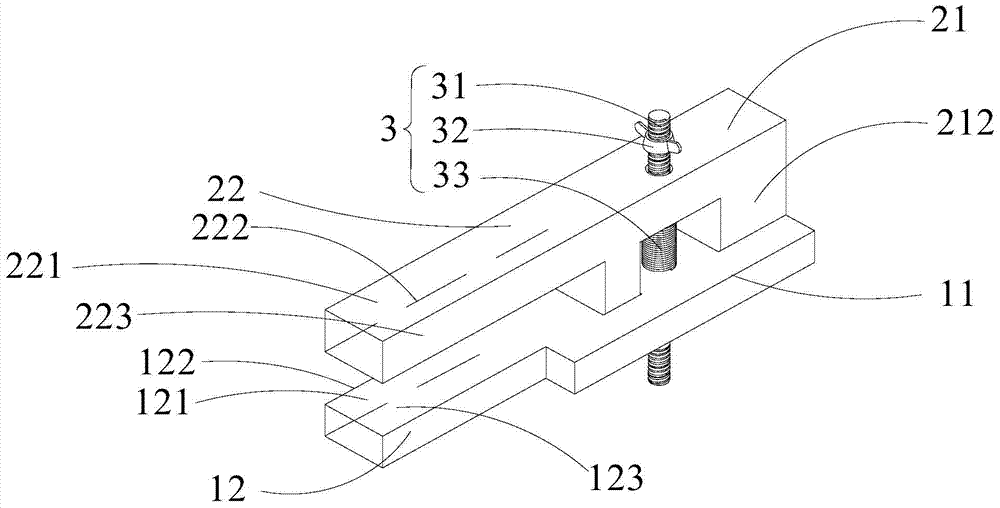

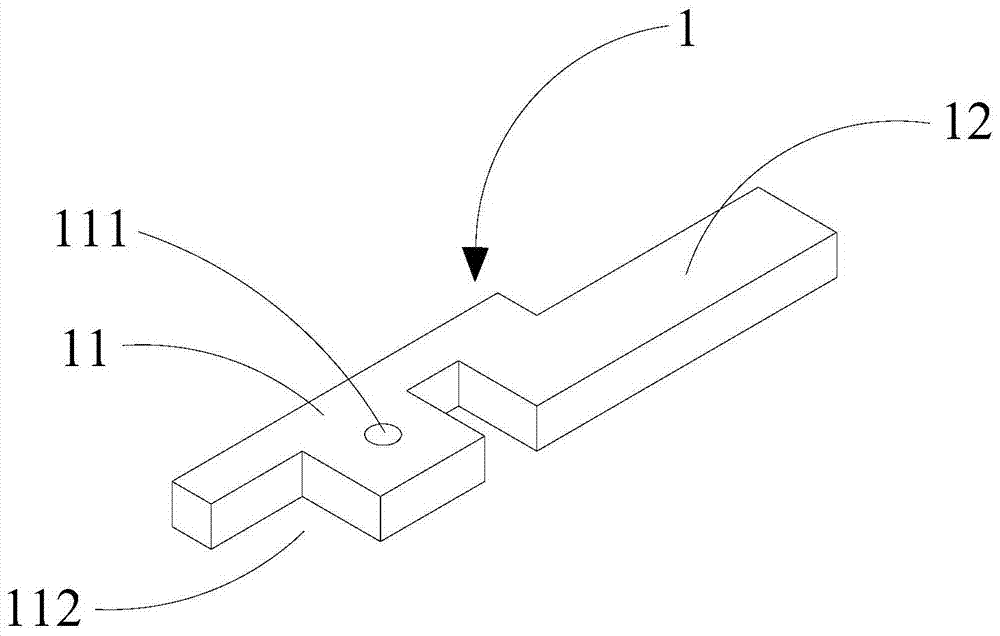

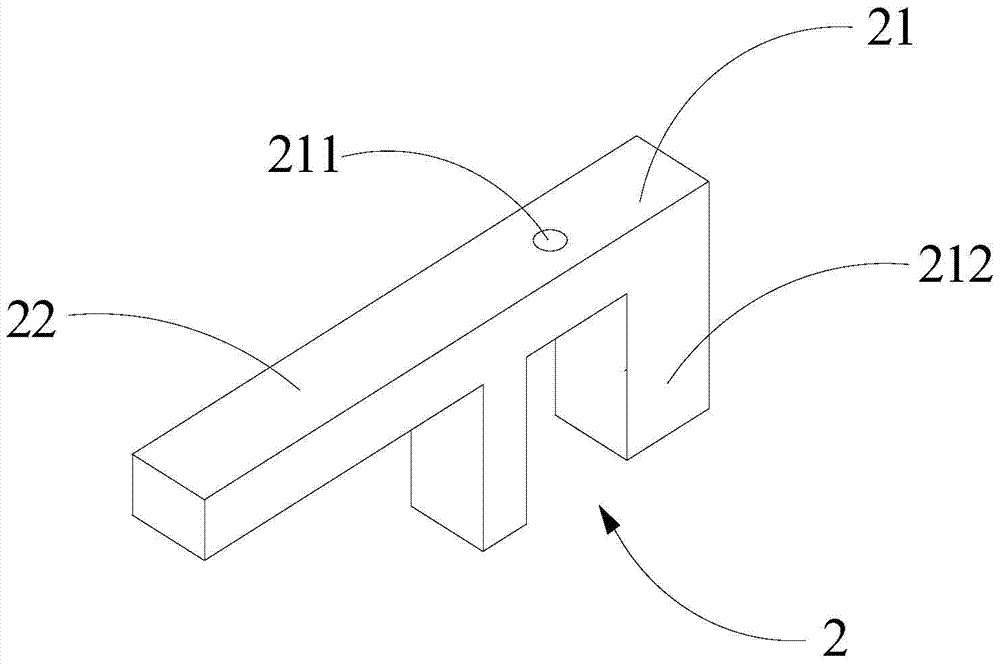

[0034] see Figure 1 to Figure 3 , The present invention provides a wire return device for boards. The wire return device includes: a first splint 1 , a second splint 2 and a fixing assembly 3 for fixing the first splint 1 and the second splint 2 together.

[0035] The first splint 1 includes: a strip-shaped first clamping portion 12 and a first connecting portion 11 connected to one end of the first clamping portion 12, the first connecting portion 11 is provided with a positioning portion, and the first connecting portion 11 is provided with a positioning portion. A through hole 111 is defined on the connecting portion 11 .

[0036] The second splint 2 includes: a strip-shaped second clamping portion 22 and a second connecting portion 21 connected to one end of the second clamping portion 22, and a through hole 211 is also opened on the second connecting portion 21, The second connecting part 21 is provided with a matching positioning part that cooperates with the positioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com