Combined tool for lead attachment and semi-automatic welding method utilizing tool

A lead welding and tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding quality, high labor cost, low work efficiency, etc., and achieve large-scale production and automation The effect of production, reducing labor input and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

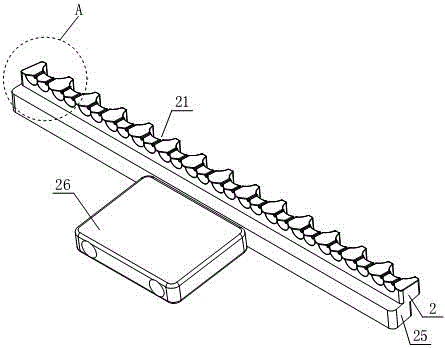

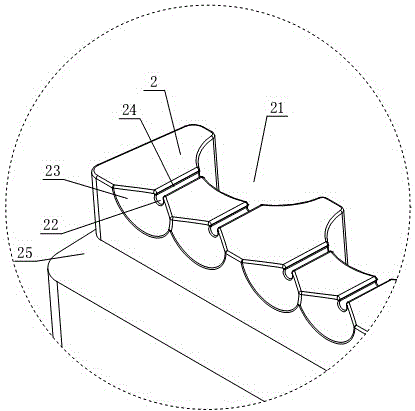

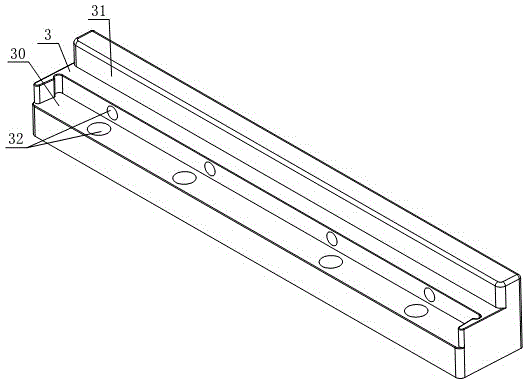

[0036] With reference to the accompanying drawings, the combined tooling for lead welding of the present invention mainly includes four parts, the first part is the wire fixing module 2, such as figure 1 and figure 2 As shown, it is in the shape of a strip, and a plurality of left half-unit clamping grooves 21 are arranged at intervals along its length direction, and a threading unit is arranged corresponding to each left half-unit clamping groove 21, and each threading unit includes one or alternately arranged More than two lead wires pass through the holes 22 . The second part is the wire retaining module 3, such as image 3 and Figure 6 As shown, the wire retaining module 3 can be buckled and matched with the wire fixing module 2 correspondingly, and a wire retaining plate 31 corresponding to the clamping groove 21 of the left half unit is provided on it. The third part is product module 4, such as Figure 4 and Figure 8 As shown, the product module 4 can be buckled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com