Closely-supporting type adjustable and simple chamferer

A chamfering device and simple technology, which are applied in the field of tightening adjustable position simple chamfering devices, can solve the problems of inability to effectively improve work efficiency, increase auxiliary time and labor intensity, and incapable of fully utilizing effective time, etc. Reliable, cost-effective, easy tightening and loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

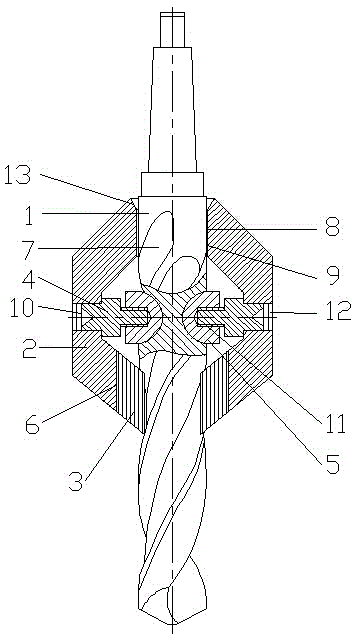

[0018] refer to figure 1 As shown, a tensioning adjustable simple chamfering device includes a chamfering device carrier 2, an alloy cutter 3, a tightening head 5 and a tightening adjustment conjoined screw 4, and the chamfering device carrier 2 is provided with an alloy The tool mounting seat 6 and the machine tool tool insertion through hole 9, the alloy tool 3 is installed on the alloy tool mounting seat 6, the chamfering device carrier 2 is also provided with an adjustment process through hole 12, connected with the tension adjustment The screw 4 is connected, and the tightening adjustment connecting screw 4 is connected with the tightening head 5 through the distance control thread 11 , and the tightening head 5 can be controlled to contact or separate from the chip removal avoidance groove 7 provided on the machine tool 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com