A saw blade damping mechanism

A saw blade damping mechanism and gland technology, which is applied in the direction of metal sawing equipment, sawing machine accessories, metal processing machinery parts, etc., can solve the problem of affecting normal sawing and affecting the service life of the saw blade. It is prone to vibration and other problems, so as to achieve the effect of improving the quality of the workpiece section, compact structure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

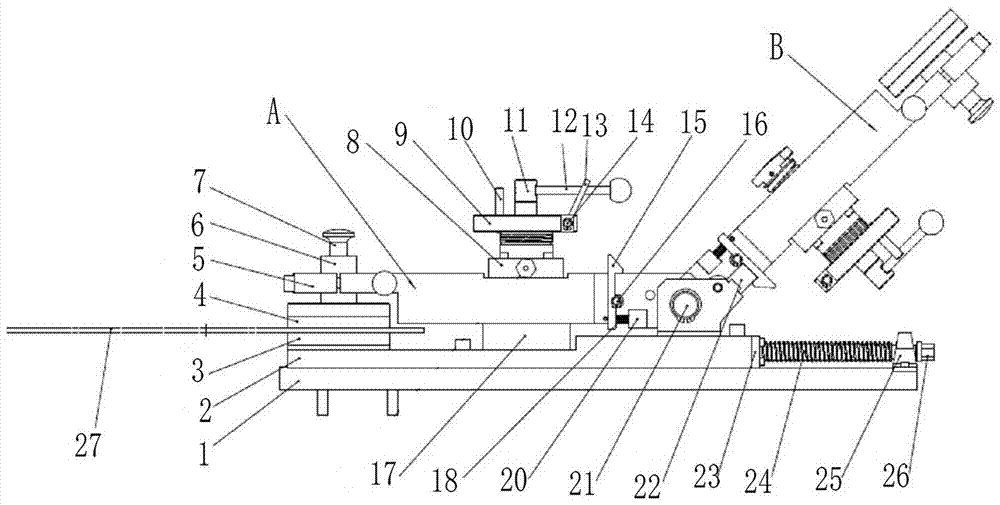

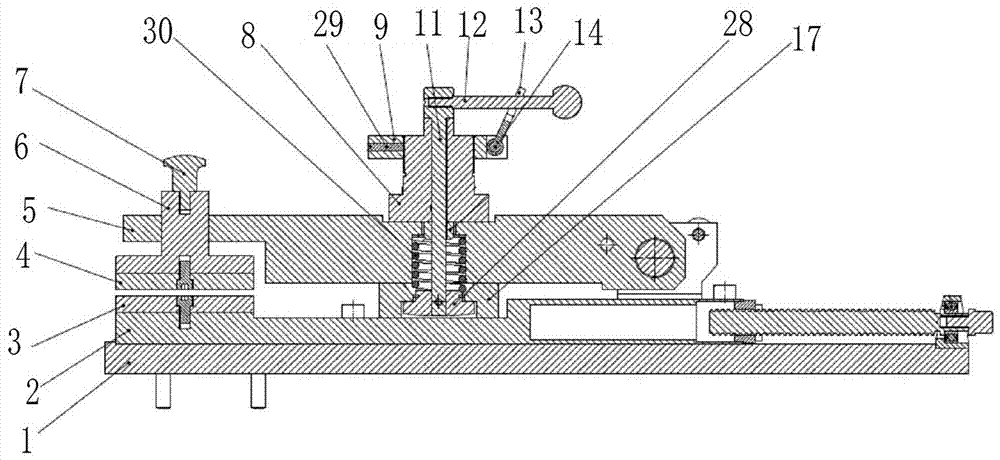

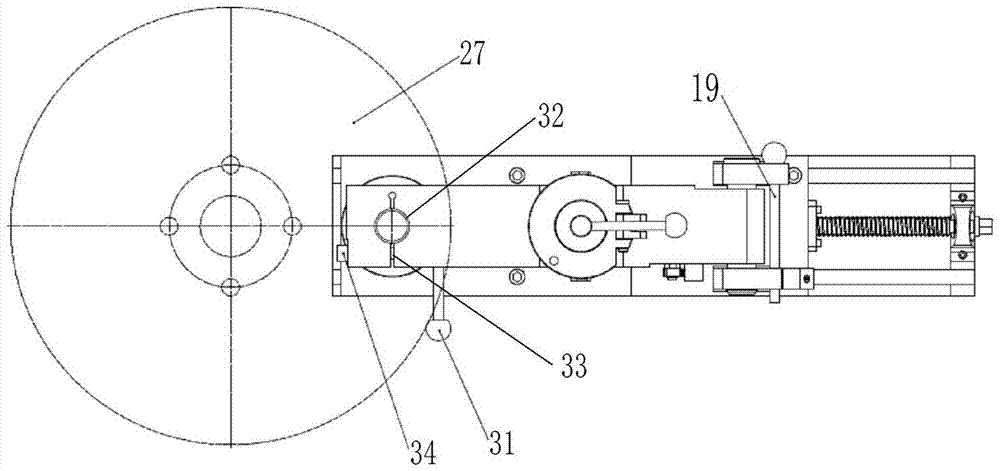

[0022] Attached below figure 1 to attach Figure 5 The present invention will be further described.

[0023] A shock-absorbing mechanism for a saw blade, comprising: a base 1, a sliding table 2 slidably installed on the base 1, a sliding table driving device arranged on the base for driving the sliding table 2 to move, and the tail end is hingedly installed through a pin III 21 For the gland 5 and the gland locking device on the sliding table 2, the front end of the gland 5 is provided with an upper pressing block 4, and the lower pressing block 3 is arranged above the front end of the sliding table 2 corresponding to the upper pressing block 4, and the gland 5 The lower end is provided with a spring II 30. When the gland 5 is locked and fixed with the base 1 by the gland locking device, the spring II 30 is compressed, and the lower pressing block 3 and the upper pressing block 4 slide with the two surfaces of the saw blade 27 respectively. Frictional surface contact. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com