Full-automatic nut inspection machine

An inspection machine and fully automatic technology, applied in sorting and other directions, can solve problems such as the decline in pass rate, large labor cost, product residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

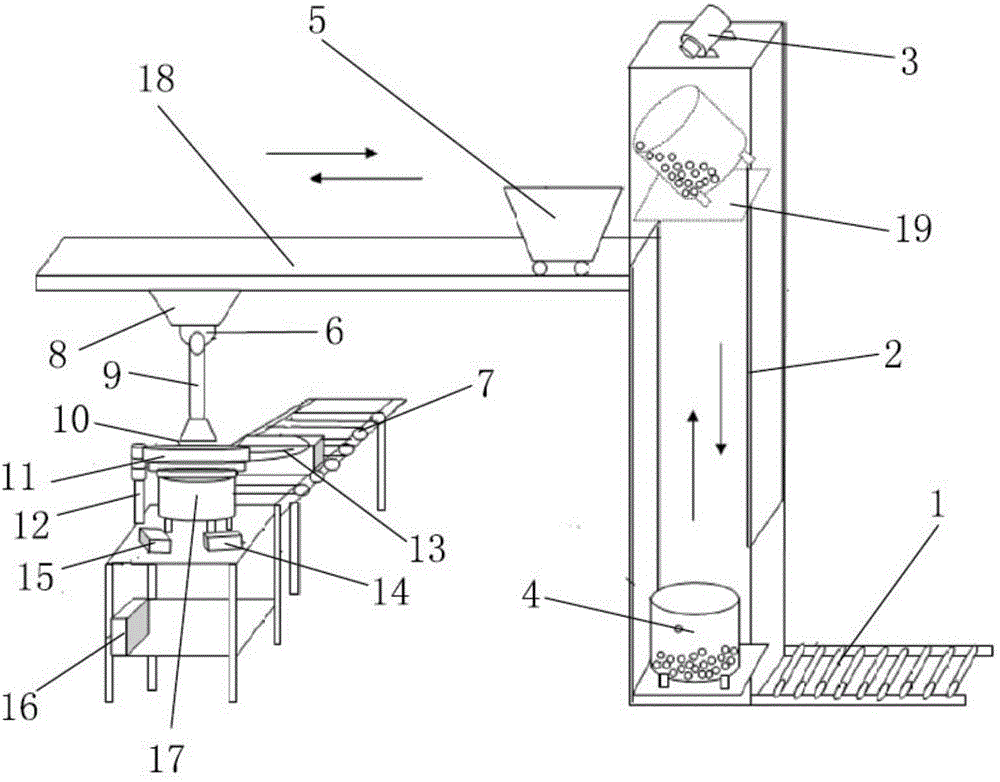

[0029] After a batch of products are electroplated and passed the outsourcing barrel plating process, these batches of products are poured into the turnover barrel 4 respectively, and then the turnover barrel 4 is placed on the roller conveyor belt 1, and the turnover barrels containing the products are transferred through the roller conveyor belt 1. The barrel 4 is sent into the feeding machine 2, and the product is transported to the upper part of the feeding machine 2 through the turnover table 19 in the feeding machine 2, and the product in the turnover barrel 4 is poured into the feeding cart 5, and then the material is fed The car 5 starts, and according to the model of the product, the feeding car 5 will send the product to the corresponding inspection assembly 17.

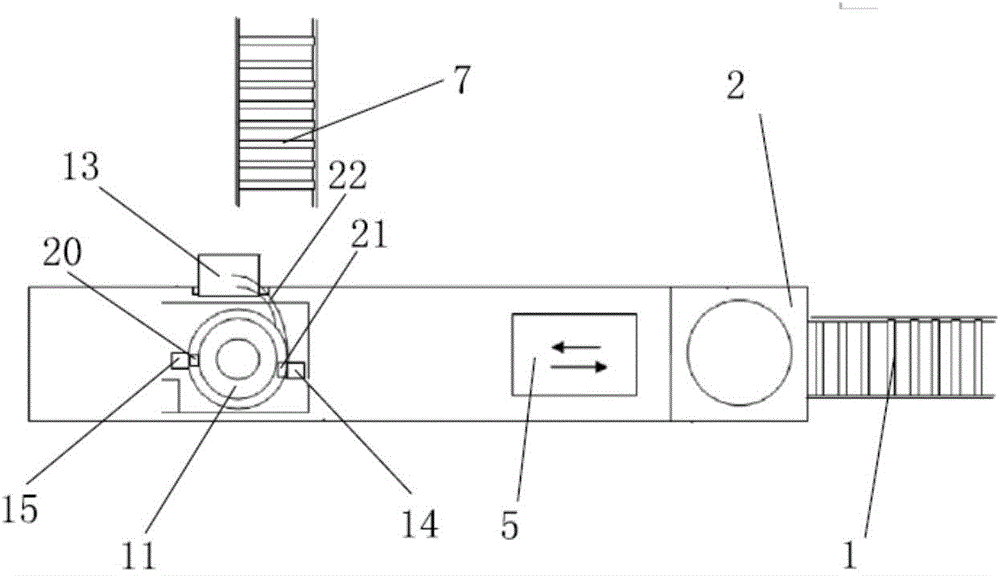

[0030] The products in the feeding cart 5 will be poured into the hopper 8 of the inspection component 17, and the hopper 8 will send the products to the detection type vibrating plate 11. Parts output port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com