Sludge settling and removal system after sewage treatment

A technology for sewage treatment and sludge, which is applied in the direction of sedimentation separation, settling tank, feeding/discharging device of settling tank, etc., can solve the problem of low cleaning efficiency, achieve good sewage treatment effect, and fast sludge removal speed , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

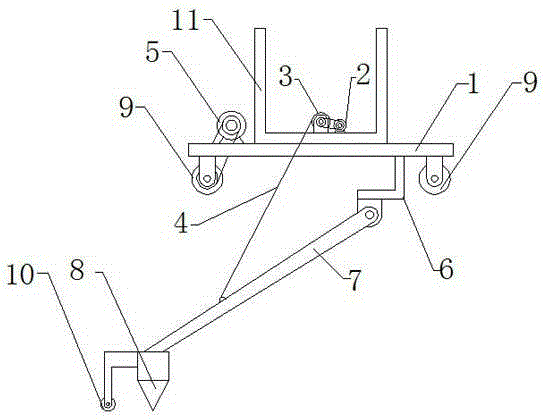

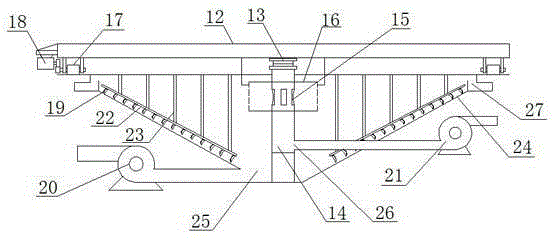

[0012] Depend on figure 1 with figure 2 As shown, the sedimentation and removal system of sludge after sewage treatment includes a sludge removal device at the bottom of the pool and a large-span sewage treatment sedimentation device. The sludge removal device at the bottom of the pool mainly includes a beam 1, a lifting drive motor 2, Lifting shaft 3, lifting rope 4, travel drive motor 5, support 6, large frame 7 and scraper 8, the two ends of the beam 1 are respectively equipped with travel wheels 9, and the travel drive motor 5 is fixedly installed on the beam 1 and connected with the driving wheel 9 transmission, the movement of the crossbeam 1 can be controlled by the travel drive motor 5, the lifting shaft 3 is movably installed on the crossbeam 1, and the lifting drive motor 2 is fixed on the crossbeam 1 and connected with the transmission of the lifting shaft 3. The upper end of the large frame 7 is movably installed on the beam 1 through the bracket 6, the trowel 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com