Damping circuit and led drive circuit with damping circuit

A damping circuit and control circuit technology, applied in the direction of electric lamp circuit layout, electric light source, electrical components, etc., can solve the problems of LED driver design difficulties, and achieve the effect of reducing the withstand voltage level, avoiding damage or inability to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

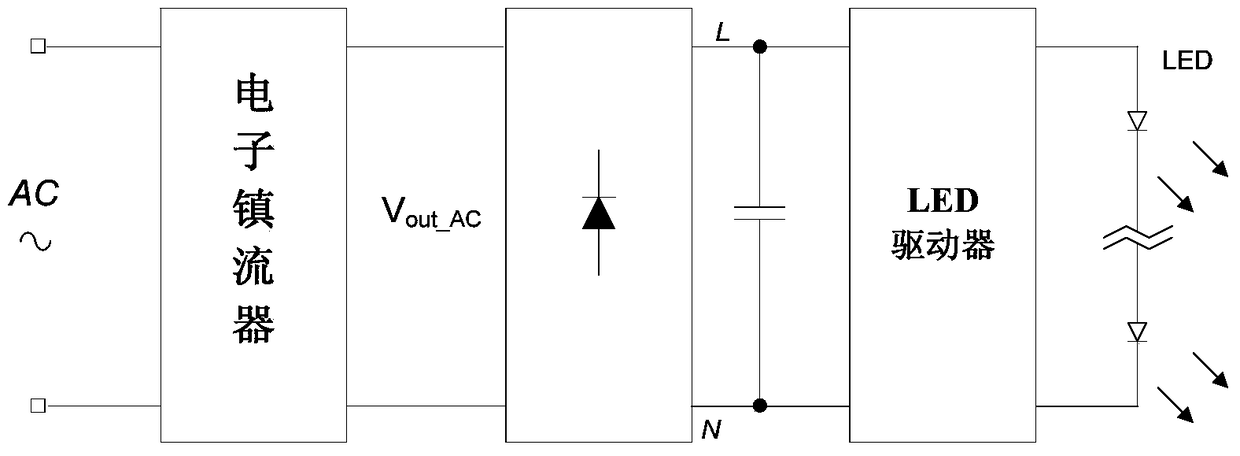

[0025] figure 1 Shown is the existing LED drive circuit, in this circuit, the AC high-frequency signal output by the electronic ballast is directly output to the LED driver after being rectified. However, since electronic ballasts are specially designed for fluorescent lamps, fluorescent lamps need to perform glow discharge during the lighting stage, and glow discharge requires a very high voltage. Therefore, the output of the electronic ballast includes two stages, one of which is the start-up stage, in which the electronic ballast outputs high voltage to make the fluorescent lamp glow, and when the fluorescent lamp is lit, the electronic ballast enters the steady-state stage, Output a normal working voltage of about 200V.

[0026] exist figure 1 In the process, the electronic ballast is directly connected to the LED driver. During the start-up phase of the electronic ballast, since the LED load is not connected, the load has no output current. At this time, the output of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com