Bucket-type coal quantity weighing metering device for industrial fire coal chain-grate boiler

A chain boiler and metering device technology, which is applied to measuring devices, automatic feeding/discharging weighing equipment, weighing, etc., can solve the problems of unsustainable accuracy of scales and easy to produce errors, etc., to reduce labor burden and operate The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

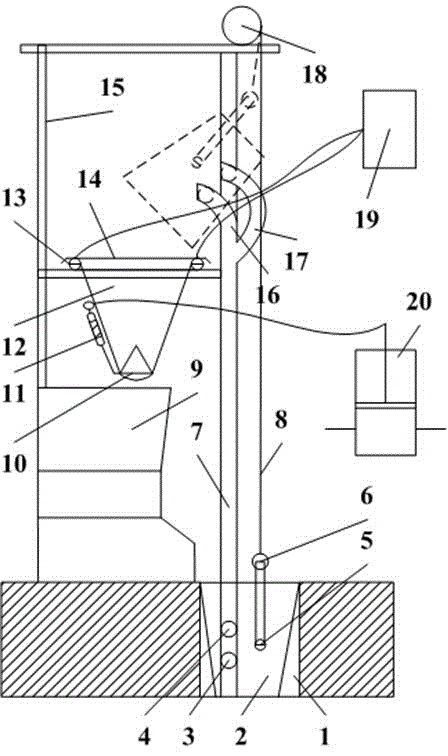

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

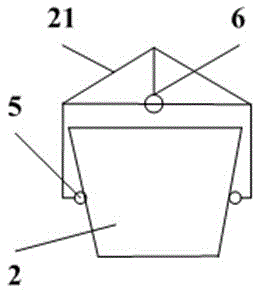

[0020] like figure 1 Shown, the present invention comprises coaling hopper 2, lifting motor 18, vertical guide rail 7, fixed support 15 and weighing coal hopper 12, and coaling hopper 2 is housed in coal unloading pit 1, and the fixed support of coal unloading pit 1 just above 15 is equipped with lifting motor 18, and the both sides between coal unloading pit 1 and lifting motor 18 are provided with vertically parallel vertical guide rail 7, as figure 2 As shown, both sides of the coal hopper 2 are fixedly connected with a fixed pulley 5, a lower pulley 3 and an upper pulley 4, the lower pulley 3 and the upper pulley 4 are all embedded in the vertical guide rail 7 and move up and down along the vertical guide rail 7, and the lower pulley 3 The distance between the upper pulley 4 and the upper pulley 4 is fixed, and the fixed pulley 5 and the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com