Ignition-under-bed combustion device with air cooling structure for circulating fluidized bed boiler

A circulating fluidized bed, air-cooled structure technology, applied in fluidized bed combustion equipment, fuel burning in a molten state, combustion ignition, etc. NOX emission, simple structure, and the effect of reducing heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

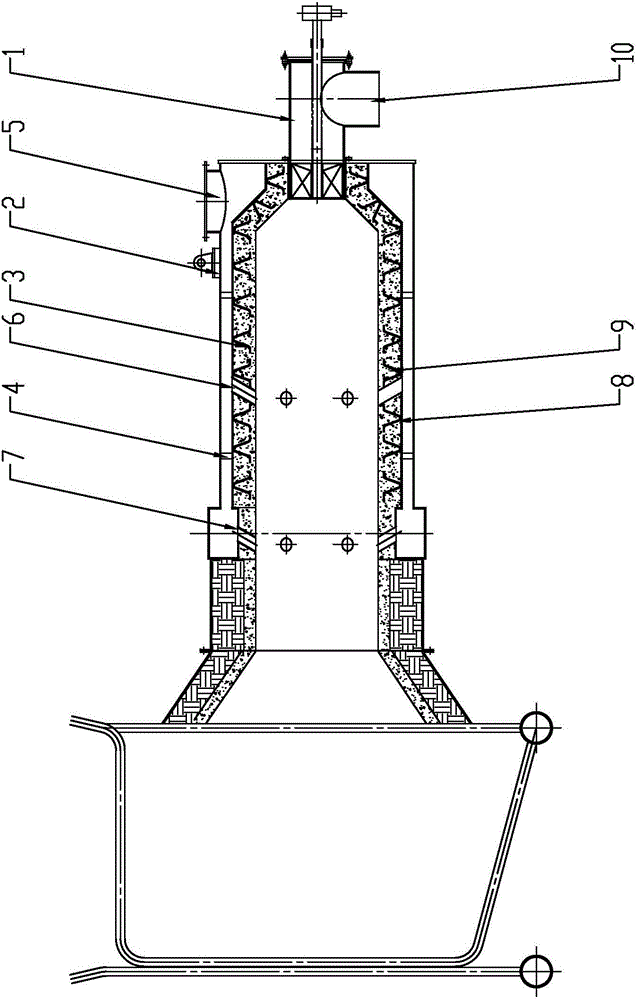

[0016] Such as figure 1 As shown, the present invention mainly includes a combustion chamber and an oil burner 1, the combustion port of the combustion chamber is connected with the oil burner 1, and the oil burner 1 is provided with a combustion air inlet 10.

[0017] The combustion chamber includes an outer cylinder body 2 and an inner cylinder body 3 located inside the outer cylinder body 2 , and the outer cylinder body 2 and the inner cylinder body 3 are welded into one body through a cylinder connector 4 . The cylinder connector 4 is made of flat steel material.

[0018] An air mixing chamber for cooling the combustion chamber 3 is provided between the combustion chamber 2 and the combustion chamber 3 , and an air mixing inlet 5 communicating with the combustion chamber is provided on the side wall of the combustion chamber 2 . A plurality of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com