A Coordinated Control System for Supercritical Circulating Fluidized Bed Units

A technology of coordinating control system and circulating fluidized bed, applied in control systems, steam generation, lighting and heating equipment, etc., can solve the problems of complex control system tasks, large thermal inertia, influence, etc., to improve the quality of power supply, prolong the Service life, the effect of improving peak shaving capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

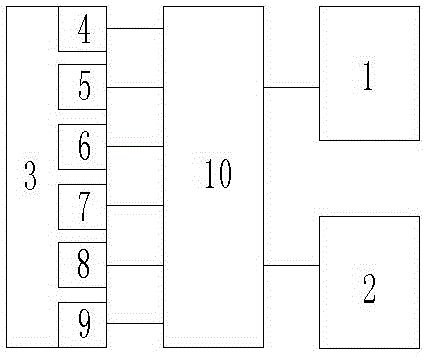

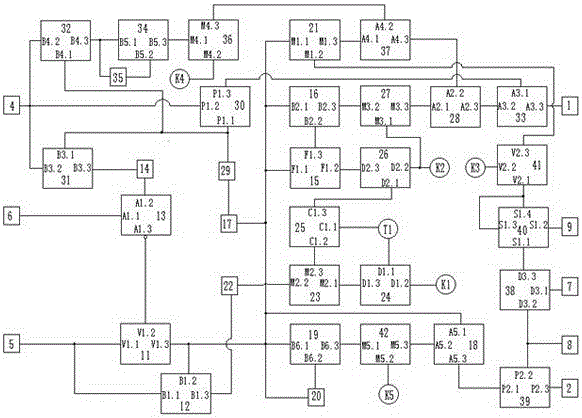

[0019] Such as figure 1 As shown, a coordinated control system for a supercritical circulating fluidized bed unit includes: a boiler main controller 1, a steam turbine main controller 2, an instruction input module 3 and a coordinated control module 10, and the instruction input module 3 includes: the main steam Measurement pressure command module 4, unit load command module 5, rate setting command module 6, unit actual total fuel volume command module 7, unit actual load command module 8 and unit load change command module 9; the main steam measurement pressure command module 4. The unit load command module 5, the rate setting command module 6, the unit actual total fuel volume command module 7, the unit actual load command module 8 and the unit load change command module 9 are all connected to the coordination control module 10. The signal input terminals are connected, and the signal output terminals of the coordination control module 10 are respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com