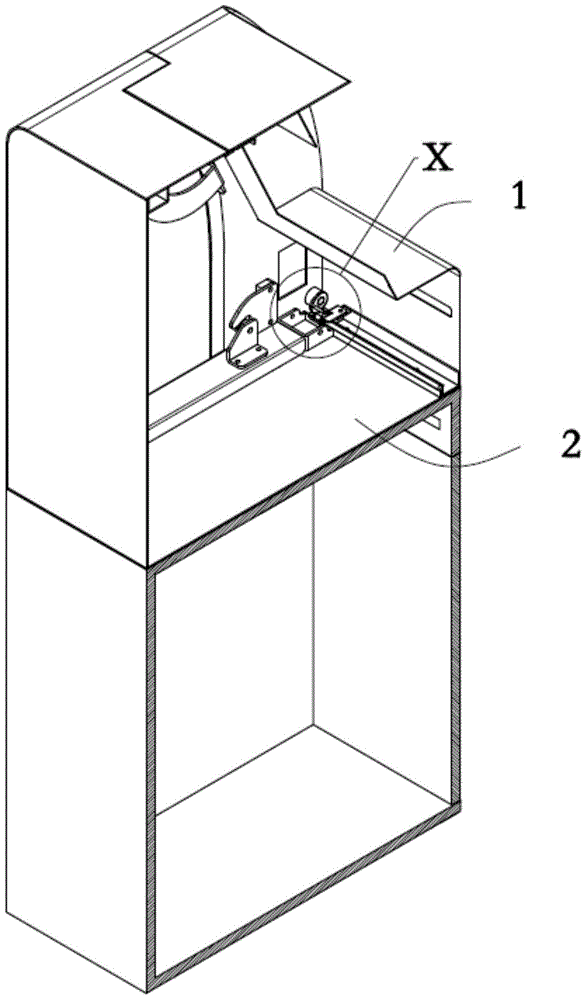

Automatic reset locking mechanism and VTM machine provided with same

A locking mechanism and automatic reset technology, which is applied in building construction, complete banking system, complete banking system, etc., can solve problems such as processing errors, panel leaks, and panels and cabinets that cannot fit perfectly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

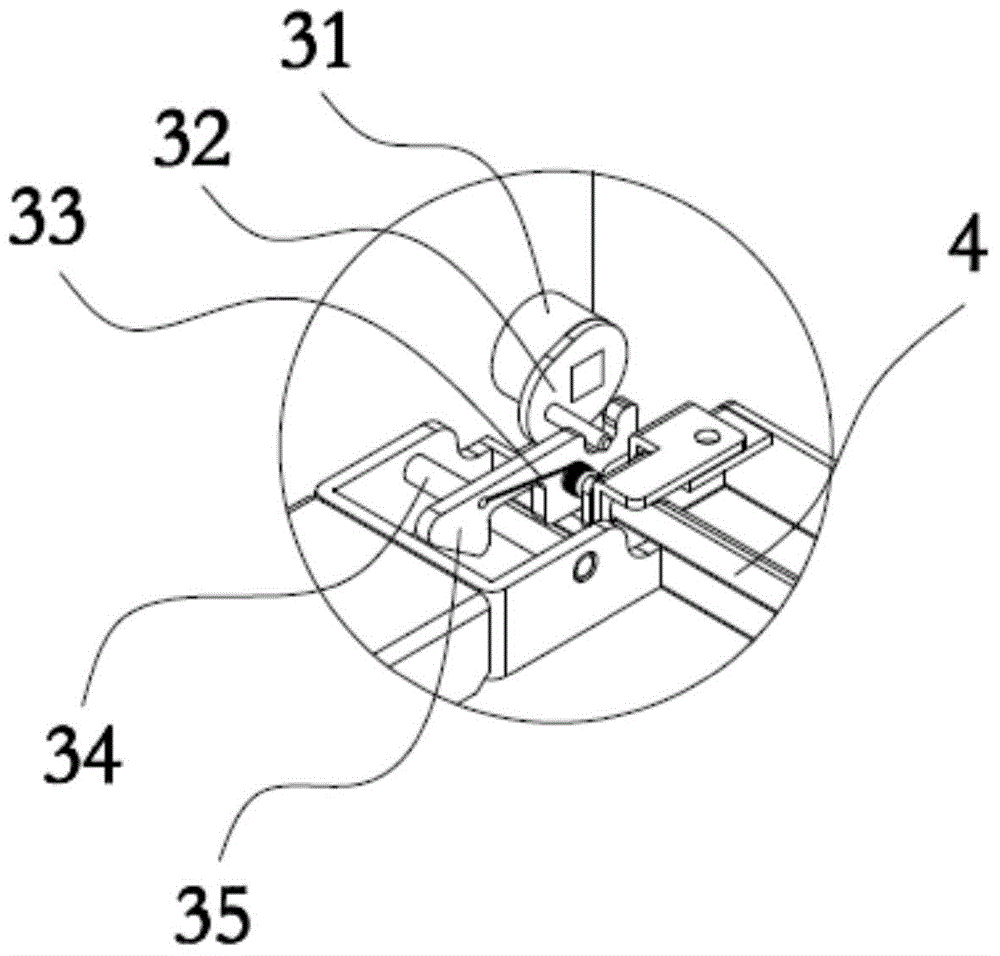

[0039] like Figure 1-4 As shown, the automatic reset locking mechanism X of the present invention includes a cam lock 31, a torsion spring 33, a hook plate, a hook pin 34 and a hook plate positioning shaft;

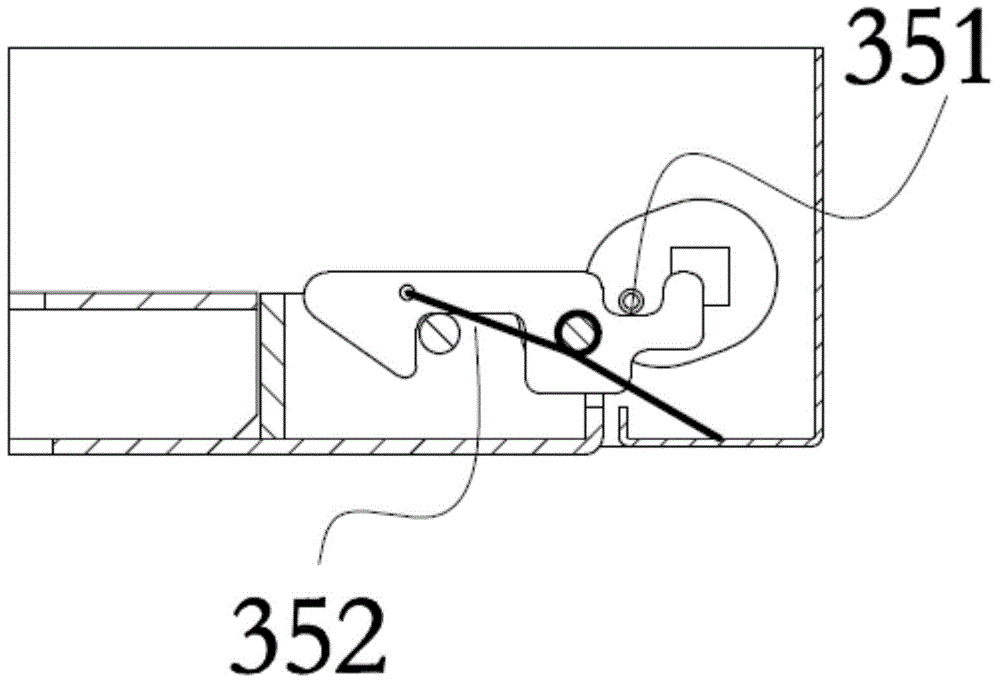

[0040] The hook plate 35 is respectively provided with a lock tongue drive slot 351 for cooperating with the lock tongue 32, a hook pin slot 352 for cooperating with the hook pin 34, a shaft hole for the hook plate positioning shaft to pass through, and a hook for the hook plate positioning shaft. The installation hole of the torsion spring 33 connected to the torsion spring 33;

[0041] The hook plate 35 is positioned and installed by the hook plate positioning shaft. The hook plate 35 can rotate around the hook plate positioning axis under the driving of the lock tongue of the cam lock 31, and pass through the hook pin slot 352 and the hook pin. 34 Lock or unlock;

[0042]The torsion spring 33 is sleeved on the periphery of the hook plate positioning shaft for realiz...

Embodiment 2

[0045] In this embodiment, the automatic reset locking mechanism X described in Embodiment 1 is used in pairs, that is, the rotary tongue lock 31, the torsion spring 33, the hook plate 35, the hook pin 34 and the hook plate positioning shaft are all two and the two hook plate positioning shafts are the same shaft body, corresponding to the attached figure 2 Both ends of the linkage shaft 4 shown in the figure.

[0046] It can be seen that the automatic reset locking mechanism X of this structural form described in this embodiment is more suitable for the panel 2 / door panel on which the lock is installed on the side, and can realize the function of synchronous locking at both ends.

Embodiment 3

[0048] like Figure 5-7 As shown, the present embodiment discloses a large-angle opening and closing hinge mechanism Y, which includes two independent pivoting elements, which are a first pivoting element 51 and a second pivoting element 52 respectively. The first pivot element 51 , the second pivot element 52 are both attached to the hinge pin 53 so that at least one of the two independent pivot elements can rotate about the hinge pin 53 . Thus, the two independent pivot elements can be rotated relative to each other.

[0049] The first pivoting element 51 and the second pivoting element 52 are provided with through holes along their respective axes; one end of the hinge pin 53 is tightly connected with the through holes opened along the axis of the first pivoting element 51 to form a whole, the hinge The other end of the pin shaft 53 is placed in the through hole opened along the axis of the second pivoting element 52; the through hole of the second pivoting element 52 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com