Ejecting device and method for erection construction of continuous beam

A jacking device and a jacking technology, which are applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of large amount of jacks, complicated jacking process, and difficult synchronization of jack movements, etc., and achieve low investment cost, The effect of simple push method, easy installation, layout and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

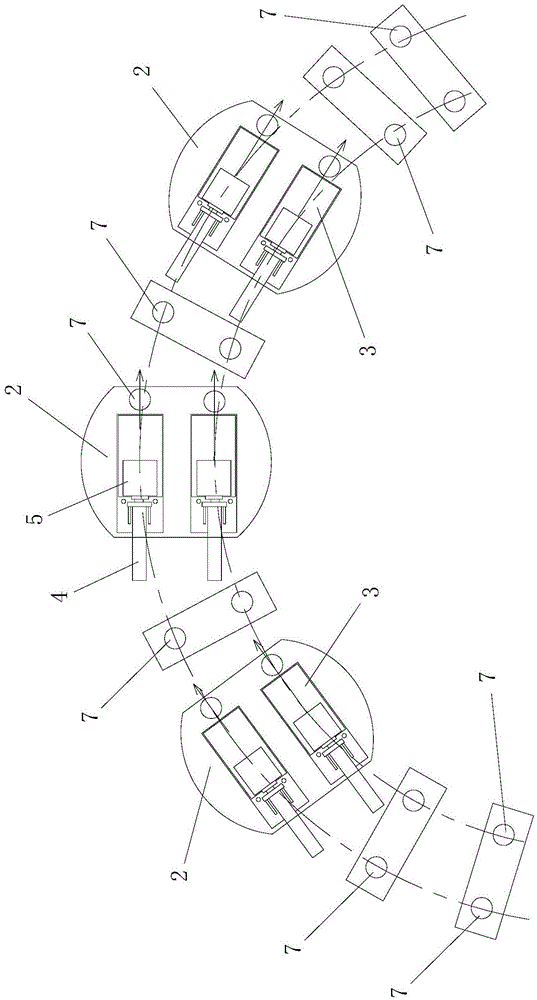

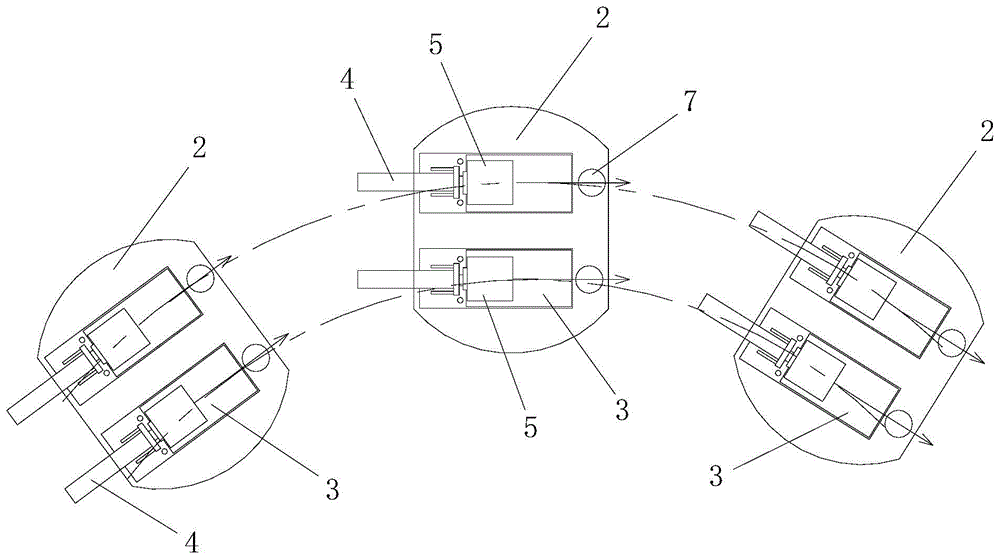

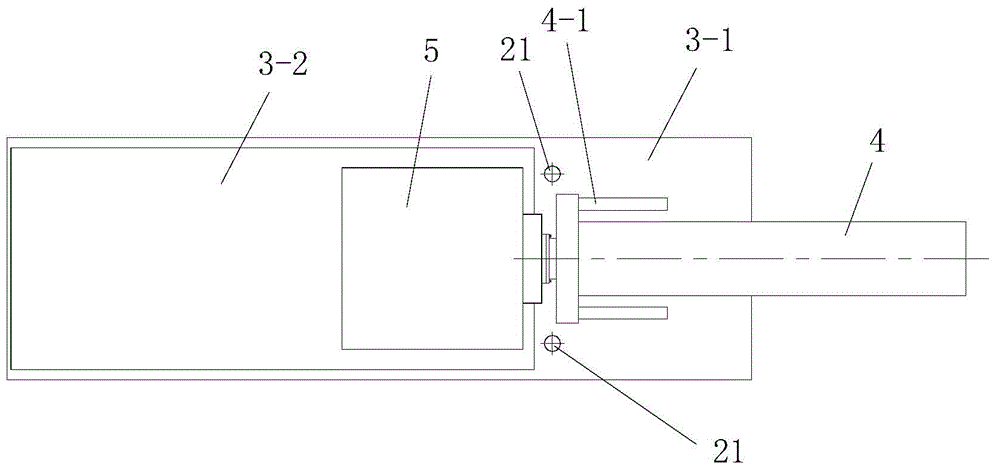

[0068] Such as figure 1A pushing device for continuous beam erection construction shown includes M beam pushing mechanisms that simultaneously push the beam body 1 to be pushed horizontally and n groups of beam body pushing mechanisms that simultaneously lift the beam body 1 to be pushed. As for the vertical jacking mechanism, the structures of the M beam body jacking mechanisms are the same and they are all arranged on the same plane, wherein M is a positive integer and M≥2. The beam body 1 to be pushed is a continuous beam erected on N permanent piers 2, and the N permanent piers 2 are arranged from front to back along the circumferential direction and are all arranged on the same arc line C , where N is a positive integer and N≥M. The M beam pushing mechanisms are respectively arranged on the tops of the M permanent piers 2, and the permanent piers 2 provided with the beam pushing mechanisms on the tops of the piers are horizontal pushing piers. The n groups of vertical j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com