A kind of nano lizn ferrite material

A ferrite material, nanotechnology, applied in the direction of magnetic properties of inorganic materials, can solve the problem of high solid-phase reaction temperature, affecting the performance of microwave phase shifters, amplitude-phase consistency and yield, material utilization and processability are not ideal And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

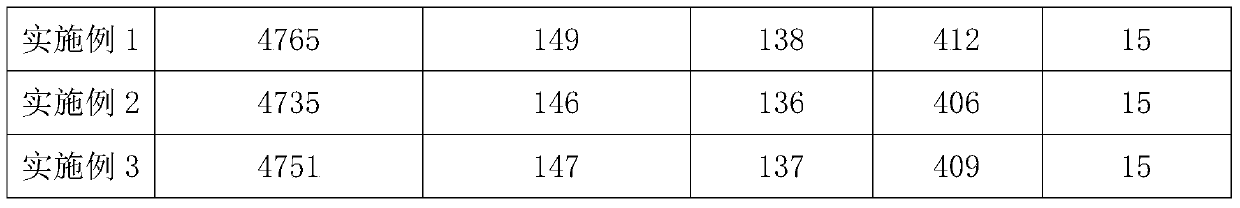

Embodiment 1

[0019] A kind of nanometer LiZn ferrite material that present embodiment 1 proposes, each raw material is taken by following proportioning:

[0020] Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 O. Bi 2 o 3 , where Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 The molar ratio is 46:6:7, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 NO of the three 3 - The sum of the moles is the basis, C 6 h 8 o 7 ·H 2 The mole fraction of O is 52%, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 The sum of the quality of O four is the benchmark, Bi 2 o 3The mass fraction of is 0.65%;

[0021] According to above-mentioned raw material ratio, prepare described nanometer LiZn ferrite material according to the following steps:

[0022] S1: Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 Mix with water to prepare matrix solution;

[0023] S2: put C 6 h 8 o 7 ·H 2 O is mixed with water to pr...

Embodiment 2

[0028] A kind of nanometer LiZn ferrite material that present embodiment 2 proposes, each raw material is taken by following proportioning:

[0029] Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 O. Bi 2 o 3 , where Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 The molar ratio is 48:7:8, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 NO of the three 3 - The sum of the moles is the basis, C 6 h 8 o 7 ·H 2 The mole fraction of O is 54%, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 The sum of the quality of O four is the benchmark, Bi 2 o 3 The mass fraction is 0.7%;

[0030] According to above-mentioned raw material ratio, prepare described nanometer LiZn ferrite material according to the following steps:

[0031] S1: Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 Mix with water to prepare matrix solution;

[0032] S2: put C 6 h 8 o 7 ·H 2 O is mixed with water to prepa...

Embodiment 3

[0037] A kind of nanometer LiZn ferrite material that present embodiment 3 proposes, each raw material is taken by following proportioning:

[0038] Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 O. Bi 2 o 3 , where Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 The molar ratio is 42:5:6, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 NO of the three 3 - The sum of the moles is the basis, C 6 h 8 o 7 ·H 2 The mole fraction of O is 48%, with Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 、C 6 h 8 o 7 ·H 2 The sum of the quality of O four is the benchmark, Bi 2 o 3 The mass fraction is 0.6%;

[0039] According to above-mentioned raw material ratio, prepare described nanometer LiZn ferrite material according to the following steps:

[0040] S1: Fe(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 Mix with water to prepare matrix solution;

[0041] S2: put C 6 h 8 o 7 ·H 2 O is mixed with water to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com