Device for supplying label sleeves

A label sleeve, equipment technology, applied in the direction of labeling, labeling, rigid containers with short marks, etc., can solve the problem of time consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

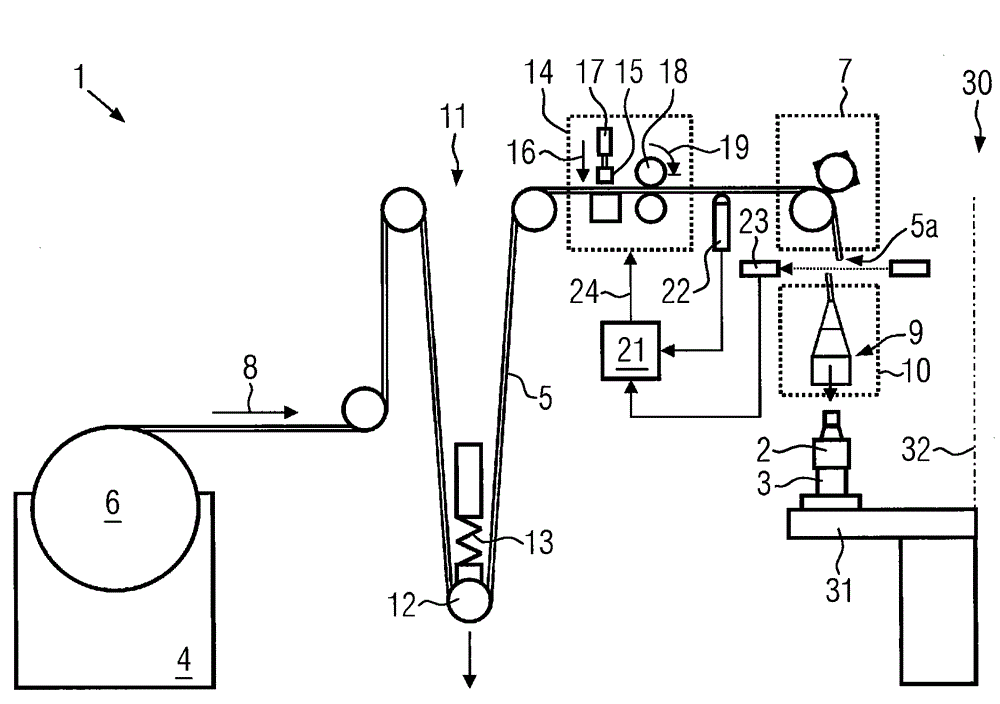

[0025] The device 1 according to the invention for supplying containers 3 , eg beverage bottles, with label sleeves 2 accordingly comprises an uncoiling device 4 for supplying a foil tube 5 from a reel 6 . Preferably, the film tube 5 is perforated transversely to the conveying direction 8 of the film tube 5 in the perforation facility 7, after which the label sleeve 2 can be torn along the transverse perforation 9 in the supply facility 10 and placed on the Container 3 on. This is well known and therefore will not be elaborated on below. In principle, it is also possible to provide the foil tube 5 with the reel 6 pre-perforated with transverse perforations 9 . Known cutting methods can likewise be used in the supply facility 10 , for example cutting the label sleeve 2 along a cutting line corresponding to the transverse perforation 9 indicated by the arrow in the figure.

[0026] Between the uncoiling installation 4 and the supply installation 10 there is a tensioning device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com