Cutting device for petroleum pipeline

A technology for oil pipelines and cutting devices, which is applied to cutters, pipe shearing devices, shearing devices and other directions for shearing machine devices, can solve the problems of uneven cutting, affecting sealing effect, low efficiency, etc., and achieves deepening cutting thickness, Guaranteed cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

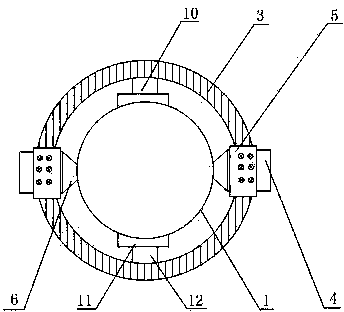

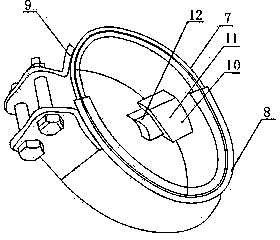

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a hoop 2 sleeved on the oil pipeline 1, a ring hole 14 is opened on the side of the hoop 2, a cutting ring 3, and a ring 15 concentric with the cutting ring 3 are fixed on one side of the cutting ring 3 And the cutter 4 fixed on the other side of the cutting ring 3, the ring 15 is rotated and arranged in the ring hole 14; the cutter 4 includes a cutting seat 5, a cutting knife 6, and the cutting seat 5 is a cavity structure with openings on both sides. The cutting knife 6 runs through the cutting seat 5; the upper surface of the cutting seat 5 and the back of the cutting knife 6 are provided with corresponding holes, and the cutting seat 5 and the cutting knife 6 are connected by bolts that simultaneously pass through the holes on the cutting seat 5 and the back of the cutting knife 6. connection, the cutting seat 5 is fixed on the upper surface of the cutting ring 3; the hoop 2 includes a semi...

Embodiment 2

[0020] On the basis of Embodiment 1, this embodiment also includes a card seat 10 arranged on the inner surface of the hoop 2; the card seat 10 includes a base 11, a card slot 12 fixed on the base 11, and the front end of the card slot 12 is an arc shaped structure, the base 11 is fixed on the inner surface of the hoop 2.

[0021] In this embodiment, the front end of the clamping groove 12 has an arc-shaped structure, so that the hoop 2 can be sleeved on the oil pipeline 1 more stably.

Embodiment 3

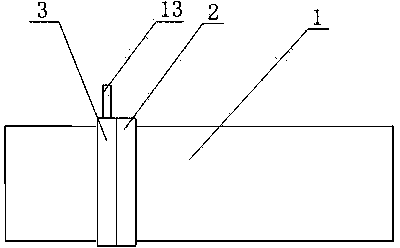

[0023] On the basis of embodiment 1 or embodiment 2, this embodiment further includes a handle 13 fixed on the side of the cutting ring 3 .

[0024] The handle 13 arranged on the cutting ring 3 can rotate the cutting ring 3 conveniently, so that the cutter 6 on the cutting ring 3 can cut the oil pipeline 1 more evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com