Hole drilling positioning die of top beam spring sleeve

The technology of a spring sleeve and a positioning mold, which is applied in the direction of a drilling mold for a workpiece, etc., can solve the problems of reducing the work efficiency of the operator, inconvenient assembly of the top beam bracket, and failing to achieve the uniformity of the workpiece processing, and achieves a simple structure and reduced Labor-intensive, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

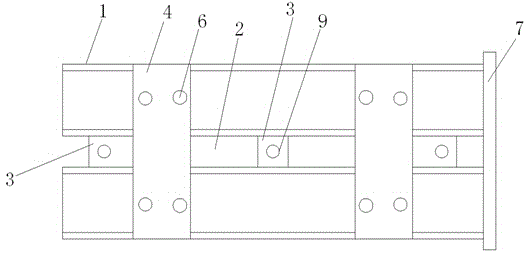

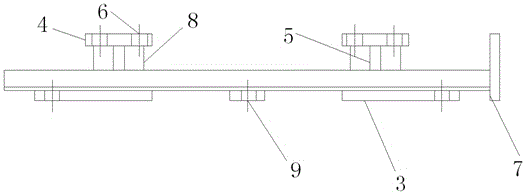

[0013] Embodiment of the present invention: a drilling positioning mold for a top beam spring sleeve, as shown in the accompanying drawings, includes at least two profiles 1 with a "U"-shaped cross section, and the inside of the "U"-shaped profiles 1 The net width is 1 / 3~1 / 2 of the diameter of the top beam spring sleeve, and its internal clear height is greater than the radius of the top beam spring sleeve. The "U" profile 1 is laid in parallel to form a gap 2, and the connecting plate 3 is placed At the bottom of the "U" profile 1, the "U" profile 1 is connected as a whole, the positioning plate 4 is placed directly above the "U" profile 1, and the positioning plate 4 and the connecting plate 3 in the gap 2 are provided. The support plate 5 realizes the fixation of the positioning plate 4, and a reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com