A gas separation method and separation system based on porous material

A porous material and gas separation technology, applied in the separation system, in the field of gas separation based on porous materials, can solve the problems of limited effect of strengthening means, affecting the reaction speed, separation coefficient and efficiency, etc. -Effect of water contact area and improvement of gas separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for gas separation based on porous materials, which specifically includes the following steps:

[0038] Step A, providing a wet reaction channel filled with porous material, the pore size of the porous material is nanoscale, in this embodiment, the porous material is mesoporous material, further, the pore size of the mesoporous material is 5-50nm;

[0039] Step B. Lower the temperature or pressurize the mixed gas to be purified to ensure the rapid progress of the hydrate formation process. In this embodiment, pressurize to 0.5-1.0Mpa or lower the temperature to 5-10°C. The pressure and The temperature range can obtain a faster reaction rate;

[0040] Step C. Pass the pretreated mixed gas into the reaction channel, the gas to be separated in the mixed gas undergoes a hydration reaction with the water / water solution in the porous material to form hydrate, and the remaining gas is discharged. During this process, the The water content in ...

Embodiment 2

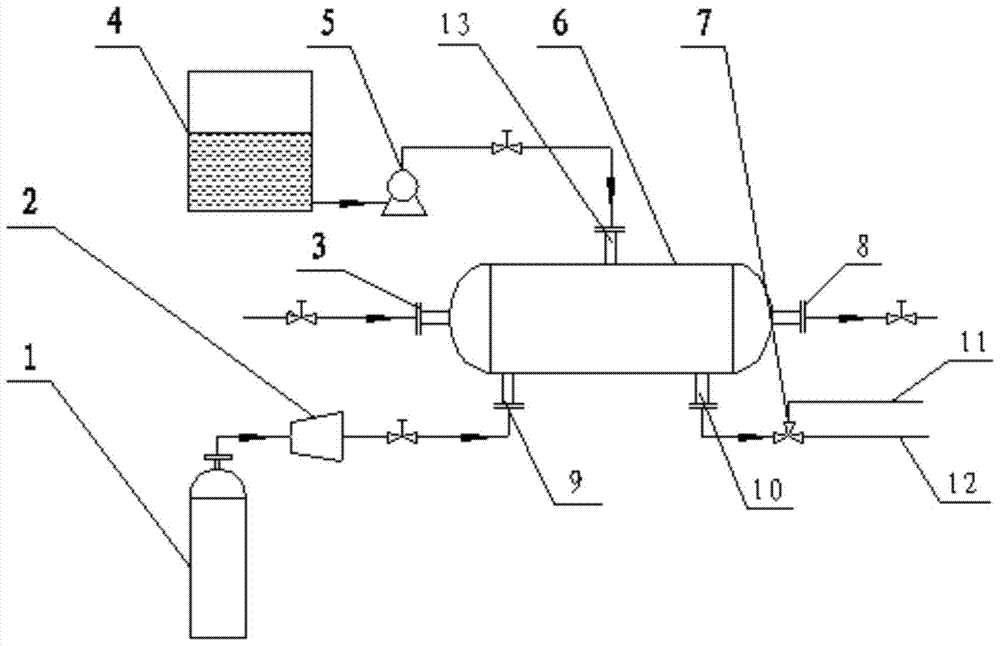

[0045] This embodiment is a separation system for gas drainage in a coal mine working face, and the gas to be separated is methane. Its structure is as figure 1 As shown, the reactor 6 is included, and the reactor 6 is filled with a medium material SBA-15 wetted by an aqueous solution, and its pore size is 7 nm. Add sodium lauryl sulfate with a concentration of 300ppm to the aqueous solution to enhance the surface activity of the solution, or add tetrahydrofuran with a molar ratio of 1:17 to reduce the reaction pressure.

[0046] The reactor 6 is provided with an air inlet 9 and an air outlet 10, the air inlet 9 is connected to the compressor 2 and the gas tank 1 in turn through the pipeline, the gas outlet 9 is connected to the reversing valve 7 through the pipeline, and the inlet port of the reversing valve 7 Connected to the gas outlet 9, the two outlets of the reversing valve 7 are respectively connected to the separation gas pipe 11 and the tail gas pipe 12, and the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com