Movement of mechanical sphygmomanometer for self-calibration production technology

A production process and blood pressure meter technology, which is applied in vascular assessment, cardiac catheterization, etc., can solve the problems of complex structure, high manufacturing, assembly and calibration costs, and high manufacturing precision, and achieve the goal of simplifying the movement, low cost, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

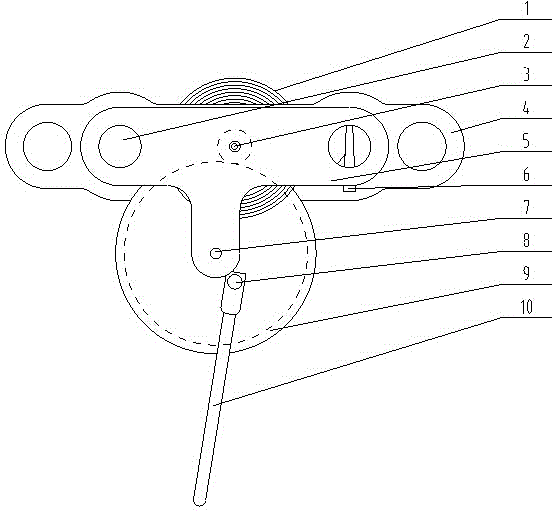

[0016] Embodiment 1: see figure 1 , the movement of a mechanical sphygmomanometer used for the self-calibration production process, the movement is composed of the following, an upper splint, a lower splint, a movement column arranged between the upper splint and the lower splint, a pointer shaft, and a device for providing elastic recovery The hairspring, the hairspring pin for fixing the hairspring, and the crank connecting rod. The upper splint is fixedly connected to the lower splint through the movement column. The pointer shaft is installed in the holes of the upper splint and the lower splint and can rotate. One end of the hairspring 1 It is fixed on the pointer shaft 3, and the other end is fixed on the movement column 2 through the hairspring pin 6, and a gear is arranged on the pointer shaft.

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, the crank connecting rod is composed of a piece gear 9, a piece gear shaft 7, a thimble pin 10 and a thimble post 8, and the piece gear shaft 7 is installed in the holes of the upper clamping plate and the lower clamping plate and is connected with The piece gear 9 is fixedly connected, and the piece gear 9 meshes with the gear on the pointer shaft 3; the piece gear 9 forms a pin connection with the thimble pin 10 through the thimble column 8; the other end of the thimble pin 10 is in contact with the air pressure elastic diaphragm box of the mechanical blood pressure gauge connected.

Embodiment 3

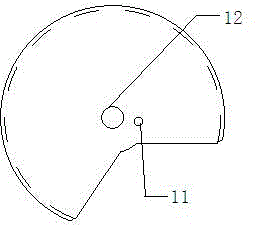

[0018] Embodiment 3: see figure 1 , as an improvement of the present invention, a small round hole 11 is provided on the said piece gear, and said thimble column is fixed on the piece gear 9 through the small round hole 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com