Hypoallergenic soybean peptide whole wheat flour as well as preparation method and application thereof

A technology for allergy to soybean and soybean protein powder, applied in the field of soybean peptides, can solve the problems of poor product taste and inability to completely eliminate the allergenicity of soybean protein, and achieve the effects of improving protein utilization, low processing cost and moderate degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

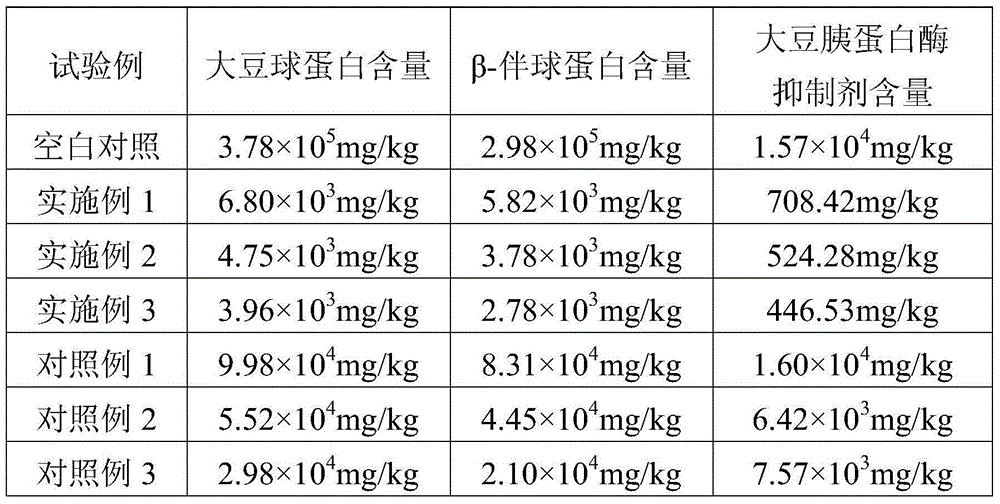

Examples

Embodiment 1

[0030] 1. Thermal denaturation

[0031] Add 500kg of soybean protein powder with a protein content of about 60% into the reaction tank, add 2500L of water into the reaction tank, stir and mix to make a soybean protein solution, heat the soybean protein solution to about 70°C, keep warm and continue stirring for about 20min to prepare denatured protein solution.

[0032] 2. The first enzymatic hydrolysis

[0033] After the temperature of the above-mentioned denatured protein solution drops to about 30°C, adjust its pH value to about 6, and add neutral protease to the denatured protein solution, wherein the dosage of neutral protease is about 100U / g soybean protein powder, maintained at 30 The first enzymatic hydrolysis is carried out at a temperature of about ℃, and after about 180 minutes of the first enzymatic hydrolysis, the first enzymatic hydrolysis solution is obtained.

[0034] 3. Second enzymatic hydrolysis

[0035] Continue to add alkaline protease and flavor protease...

Embodiment 2

[0042] 1. Thermal denaturation

[0043] After adding 500kg of soybean protein powder with a protein content of about 60% into the reaction tank, add 4000L of water into the reaction tank, stir and mix to make a soybean protein solution, heat the soybean protein solution to about 80°C, keep warm and continue stirring for about 40min to prepare denatured protein solution.

[0044] 2. The first enzymatic hydrolysis

[0045] After the temperature of the above-mentioned denatured protein solution drops to about 50°C, adjust its pH value to about 7, and add neutral protease to the denatured protein solution. The first enzymatic hydrolysis is carried out at a temperature of about ℃, and after about 120 minutes of the first enzymatic hydrolysis, the first enzymatic hydrolysis solution is obtained.

[0046] 3. Second enzymatic hydrolysis

[0047] Continue to add alkaline protease and flavor protease to the above first enzymolysis solution, wherein the amount of alkaline protease is ...

Embodiment 3

[0051] 1. Thermal denaturation

[0052] After adding 500kg of soybean protein powder with a protein content of about 60% into the reaction tank, add 5000L of water into the reaction tank, stir and mix to make a soybean protein solution, heat the soybean protein solution to about 90°C, keep warm and continue stirring for about 60min to prepare denatured protein solution.

[0053] 2. The first enzymatic hydrolysis

[0054] After the temperature of the above-mentioned denatured protein solution drops to about 60°C, adjust its pH value to about 8, and add neutral protease to the denatured protein solution, wherein the dosage of neutral protease is about 100U / g soybean protein powder, maintained at 60 The first enzymatic hydrolysis is carried out at a temperature of about ℃, and the first enzymatic hydrolysis solution is obtained after the first enzymatic hydrolysis for about 60 minutes.

[0055] 3. Second enzymatic hydrolysis

[0056] Continue to add alkaline protease and flavo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com