Centralized automatic feeding and oxygenation system for aquaculture

A kind of aquaculture, centralized technology, applied in application, fish farming, animal husbandry, etc., to achieve the effect of convenient feeding, large range and long feeding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] In this embodiment, a centralized automatic feeding and aeration system for aquaculture is designed in view of the problems existing in the existing feeding machines and the needs of large-scale aquaculture.

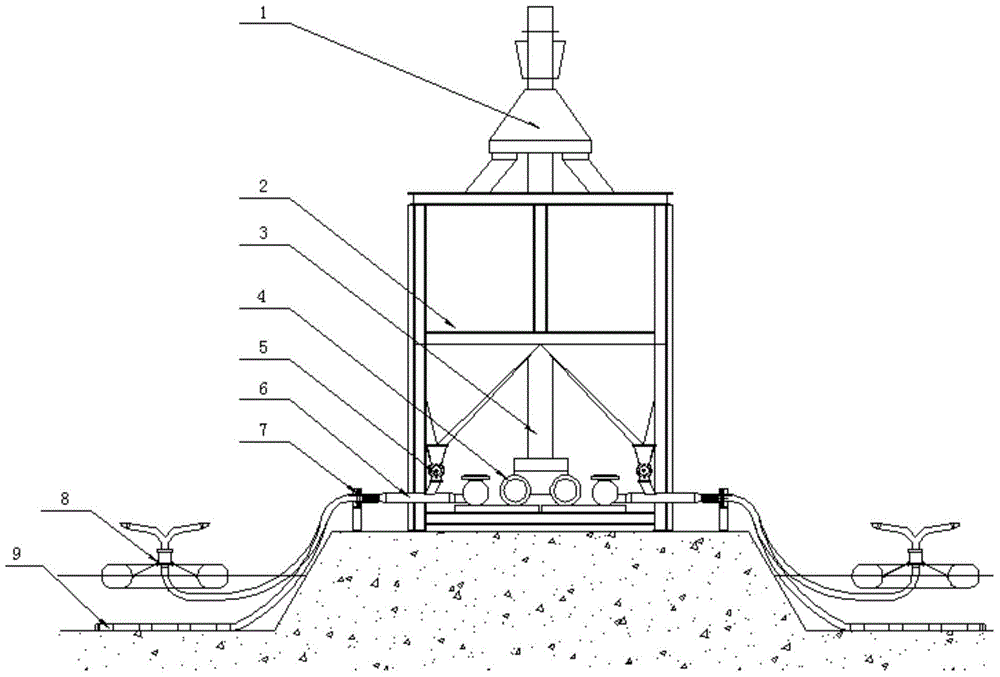

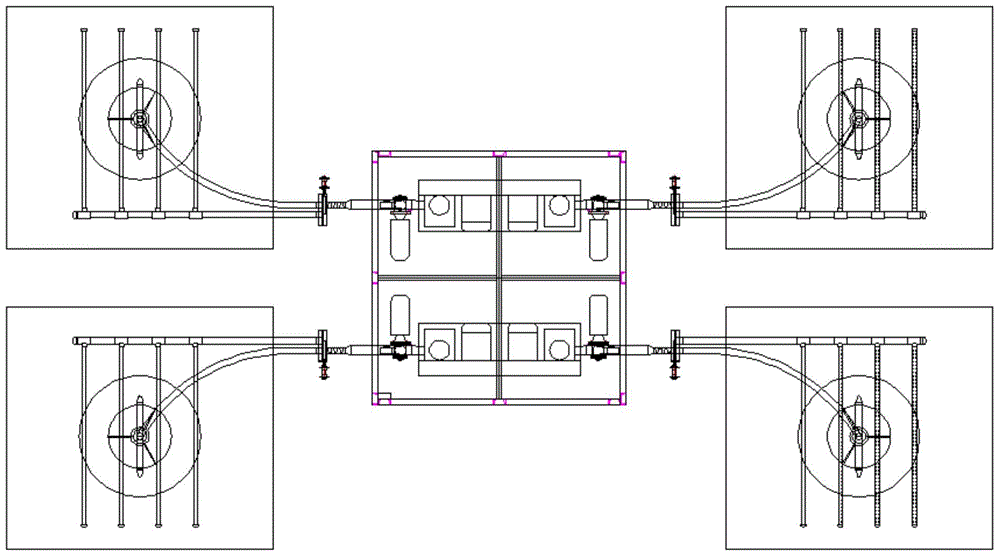

[0031] see Figure 1-Figure 2 , a centralized automatic feeding and oxygenation system for aquaculture, in a group of standardized aquaculture ponds, a feed feeding station is set correspondingly for every 4 or more ponds, and the feed feeding station includes a distributor 1, a combined feed bin Group 2, lifting feeding machine 3, high-pressure fan 4, frequency conversion feeding device 5, feeding air pipe 6, pneumatic tee 7, control unit, weighing unit; the combined feed bin group 2 is used as a feed storage warehouse, directly Receive the feed from the feed transport vehicle; lift the feeder 4 to lift the feed, and distribute i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com