Device and method for preparing waveguide and grating by femtosecond laser etching

A waveguide grating, femtosecond laser technology, applied in diffraction grating, optical mechanical equipment, photoengraving process of pattern surface, etc., can solve the problems of complex processing, difficulty in ensuring the high parallelism of LPWG waveguide, time-consuming process, etc., to achieve simplification The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

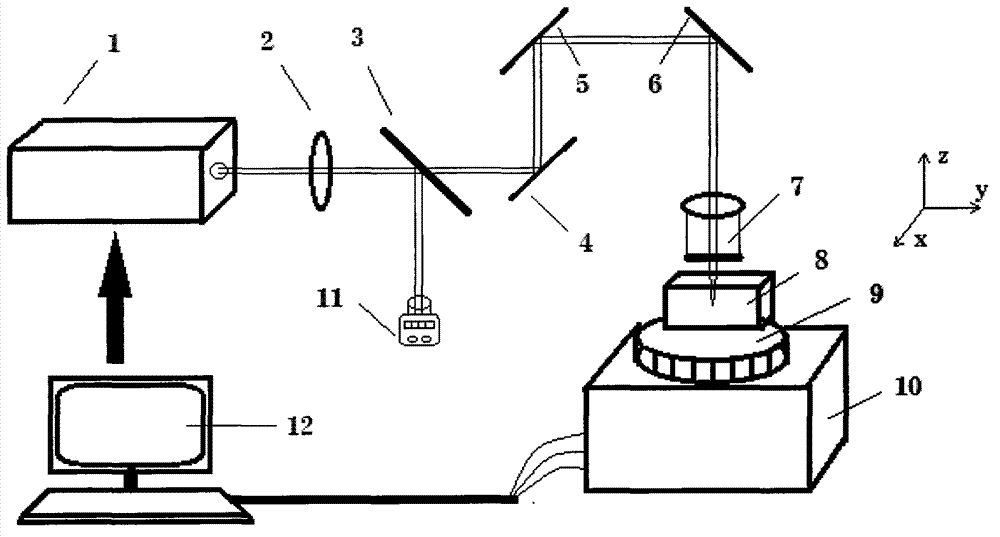

[0013] exist figure 1 In this embodiment, the femtosecond laser preparation long-period waveguide grating processing device consists of a femtosecond laser 1, an optical polarizer 2, a beam splitter 3, a first reflector 4, a second reflector 5, a third reflector 6, a display Micro-objective lens 7, lithium niobate crystal 8, precision rotating platform 9, three-dimensional electric translation platform 10, optical power meter 11 and computer 12 are connected in sequence.

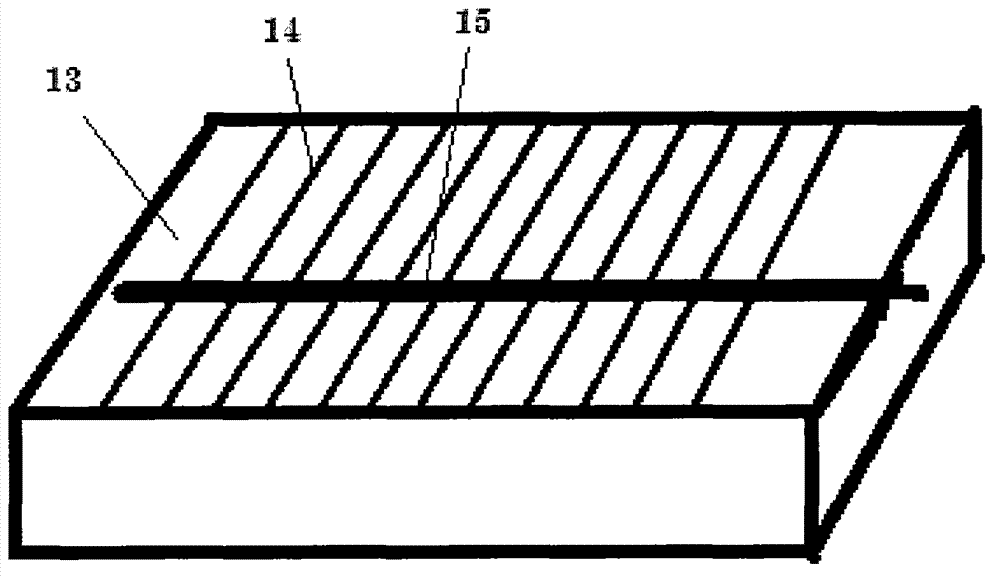

[0014] The femtosecond laser 1 generates a laser with a repetition frequency of 76 MHz and a pulse width of 50 femtoseconds. After passing through the microscope objective lens 7, the laser is focused on the crystal with a depth of 400 μm. The three-dimensional electric translation stage 10 is fixed on it at a speed of about 5 mm / s. Lithium niobate crystal 8 moves on the surface, and the writing of the first optical waveguide 15 is completed. After that, the average laser power was changed to 350 milliwatts...

Embodiment 2

[0017] exist figure 1 In this embodiment, the femtosecond laser preparation long-period waveguide grating processing device consists of a femtosecond laser 1, an optical polarizer 2, a beam splitter 3, a first reflector 4, a second reflector 5, a third reflector 6, a display Micro-objective lens 7, lithium niobate crystal 8, precision rotating platform 9, three-dimensional electric translation platform 10, optical power meter 11 and computer 12 are connected in sequence.

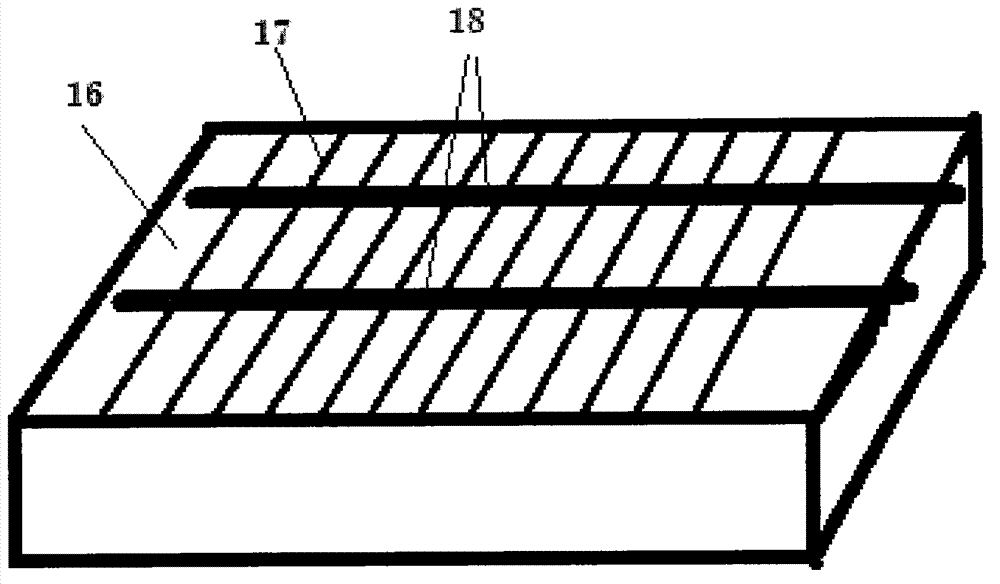

[0018] The output laser of the femtosecond laser is a laser with a repetition frequency of 76 MHz and a pulse width of 50 femtoseconds. After passing through the microscope objective lens 7, the laser is focused on the lithium niobate crystal at a depth of 400 μm. The movement of the lithium niobate crystal 8 fixed thereon completes the writing of the second optical waveguide 18, wherein the two waveguides are on the same horizontal plane and are strictly parallel. Afterwards, the average laser power was ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com