On-line fault diagnosis device and method for capacitive current transformer

A fault diagnosis device, current transformer technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve problems such as difficult to diagnose initial faults, not much insulating oil, unable to detect moisture in the capacitive screen of the transformer, etc., to achieve prevention Effects of Grid Incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

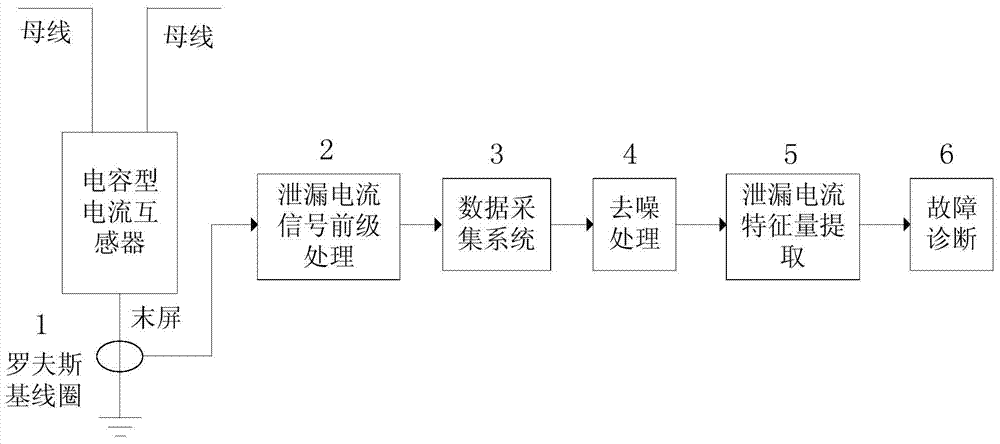

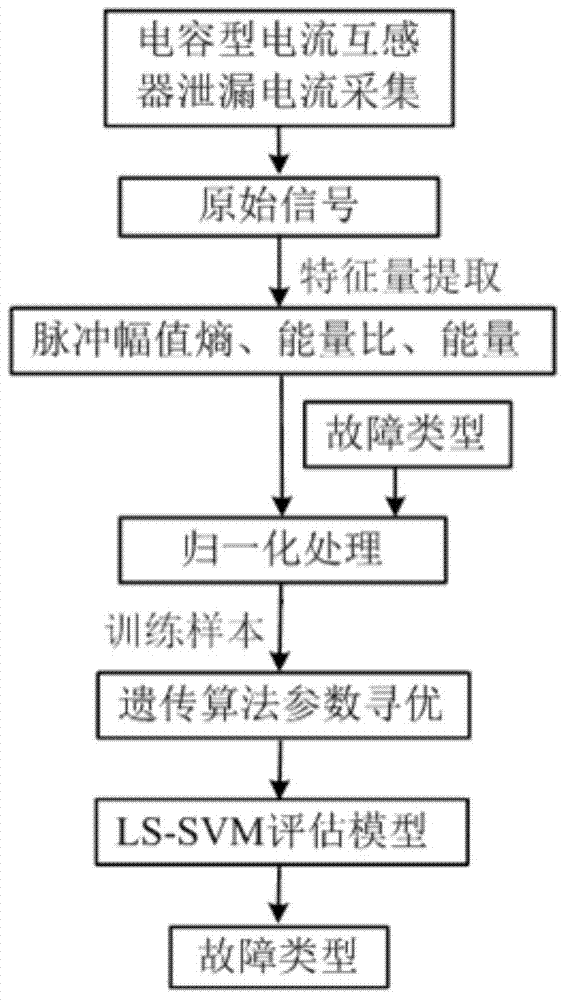

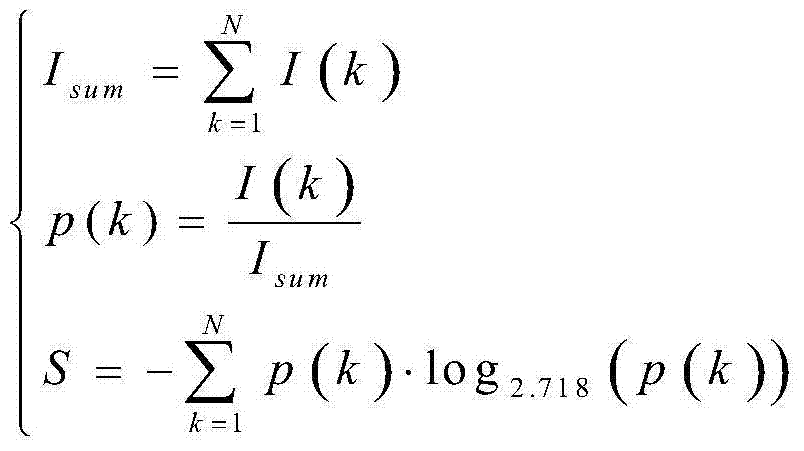

[0028] see figure 1 , The device of the present invention includes a Rowski coil, pre-processing of leakage current signals, a data acquisition system, denoising processing, extraction of characteristic quantities of leakage current, and fault diagnosis. The Rovsky coil can be customized in the manufacturer according to the range and accuracy of leakage current acquisition; the pre-processing of the leakage current signal is composed of a signal amplification circuit, which amplifies the leakage current signal to the acceptable input voltage range of the NI data acquisition card; the data acquisition system consists of Composed of personal computer, NI USB-6215 data acquisition card and supporting LABVIEW software; the denoising process adopts the principle of wavelet threshold value denoising to denoise the leakage current signal; the leakage current feature value is extracted by analyzing and processing the leakage current signal , to extract the sensitive characteristic qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com