Insulating mat testing device

A test device and technology for insulating blankets, which are applied in the direction of testing dielectric strength and other directions, can solve problems such as difficulty in testing insulating blankets, and achieve the effects of improving convenience and effectiveness and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

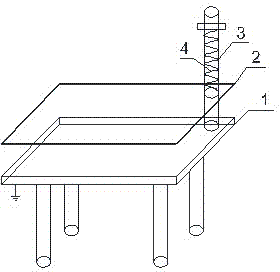

[0017] like figure 1 As shown, an insulating blanket test device consists of a base [1], a cover plate [2], a pillar [3], a spring [4], and a high-voltage lead wire [5]; it is characterized in that the pillar [3] is circular , the pillar [3] is fixed on a corner of the base [1]; the size of the cover [2] is the same as that of the base [1] desktop, and the cover [2] can rotate horizontally along the pillar [3]; put it on the pillar [3] Spring [4] is arranged, and spring [4] is fixed on the cover plate [2].

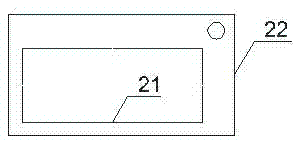

[0018] like figure 2 As shown, in order to prevent the cover plate [2] from discharging on the base [1] during the test; the cover plate [2] is composed of a stainless steel plate [21] and an epoxy resin plate [22], and the stainless steel plate [21] is made of super glue Bonded on the epoxy resin plate [22]; the high-voltage lead wire [5] is connected with the stainless steel plate [21].

[0019] When conducting the insulation blanket test, the base [1] is grounded, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com