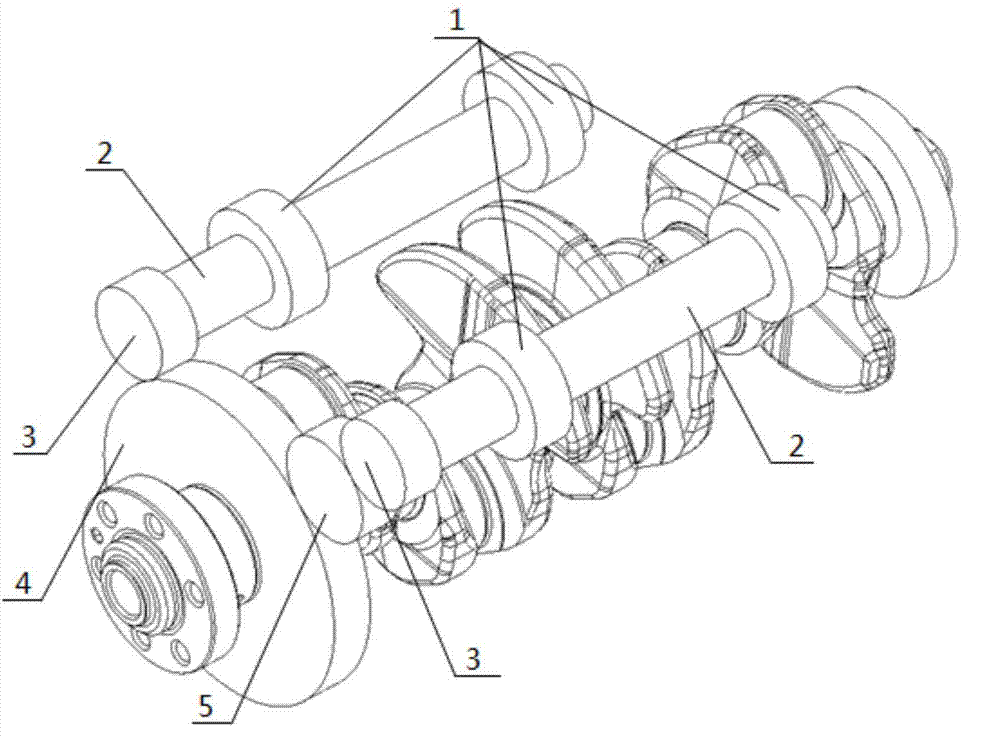

Driving structure of four cylinder engine balance shaft

A technology of driving structure and balance shaft, applied in the field of balance shaft, can solve problems such as affecting the work of parts, and achieve the effect of simplifying the structure and saving layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A balance shaft drive structure for a four-cylinder engine, including two pairs of support bearings 1, two balance shafts 2, two transmission gears 3, one drive gear 4 and one idler gear 5, the two balance shafts 2 are installed on four On the left and right sides of the cylinder machine body, transmission gears 3 are installed on the front ends of two balance shafts 2, and an idler gear 5 is installed on the side of one balance shaft 2 where the transmission gear 3 is installed, and the idler gear 5 is engaged with the transmission gear 3 , the balance shaft 2 is directly driven by the transmission gear 3 or driven by the idler 5, and the reverse rotation can be realized through the idler 5; the body of the four-cylinder engine is designed with a mounting hole for the balance shaft 2, and the support bearing 1 is installed in the mounting hole with interference , the balance shaft 2 is loaded from one end of the four-cylinder engine body, and is thrust, and each balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com