Two-fluid atomizing nozzle

An atomizing nozzle and two-fluid technology, which can be used in liquid spray devices, spray devices, etc., can solve the problems of sticking tower agglomeration and insufficient heat exchange, and can prevent sticking tower agglomeration, sufficient heat exchange, and small water content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

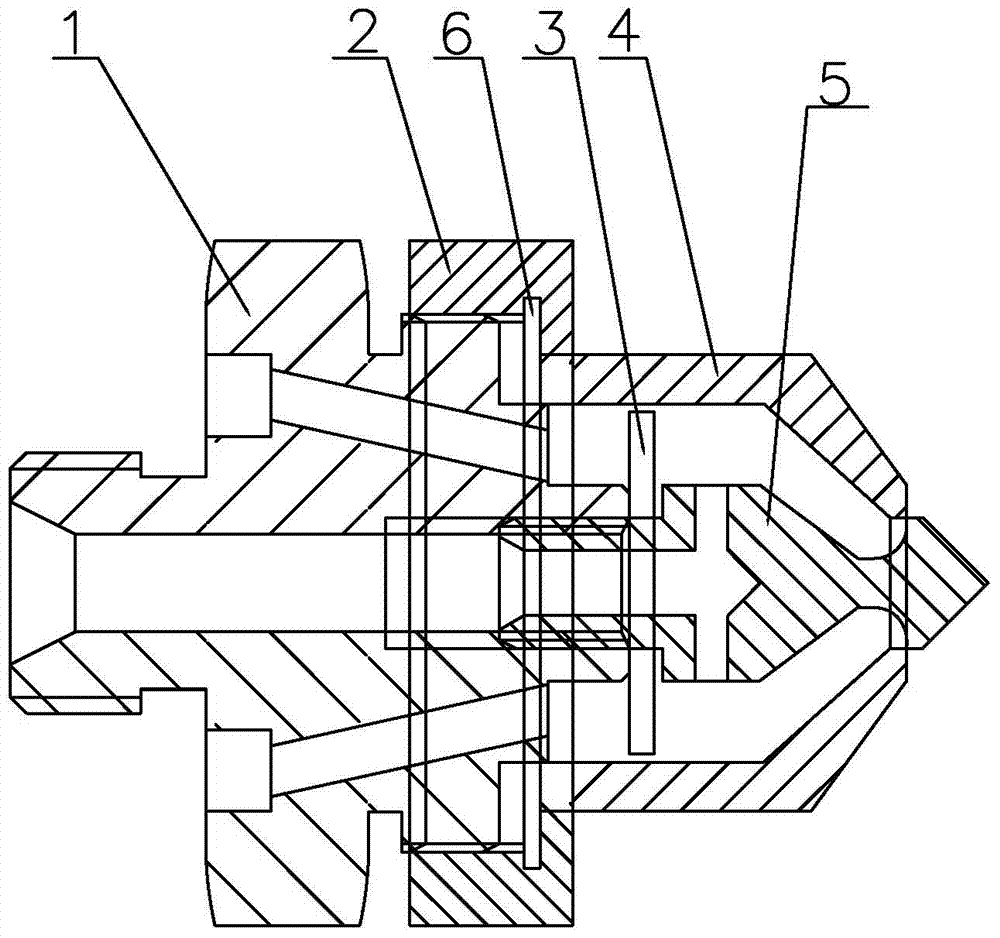

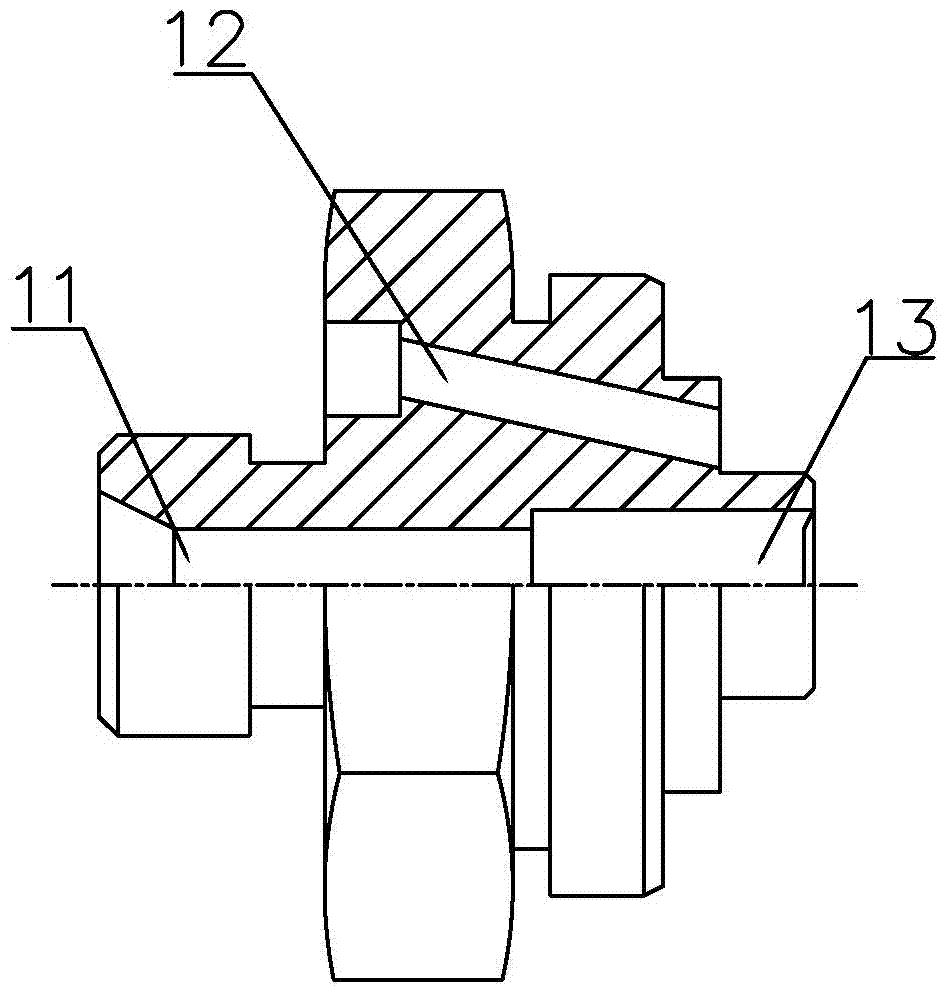

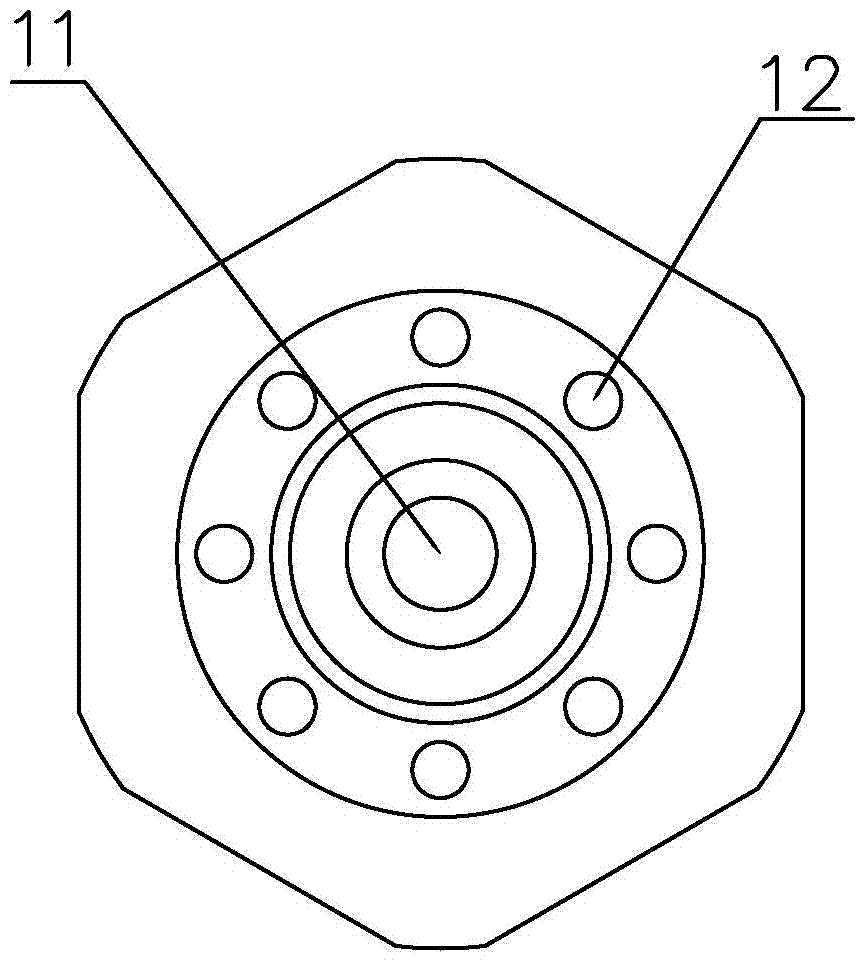

[0025] Such as figure 1 As shown, a two-fluid atomizing nozzle includes a distribution seat 1 and a nozzle 4, the middle position of the distribution seat 1 is provided with a material hole 11, and the periphery of the material hole 11 is provided with a ventilation hole 12, such as figure 2 and image 3 As shown, the material hole 11 is located in the middle of the distribution seat 1 and runs through the distribution seat 1 , and there are eight ventilation holes 12 evenly distributed around the material hole 11 , and the ventilation holes 12 also pass through the distribution seat 1 . The distribution seat 1 is fixedly connected with the nozzle 4 by a nut 2, and a material mixing tank 41 is formed in the nozzle 4, and the material hole 11 and the ventilation hole 12 are both communicated with the material mixing tank 41. Such as Figure 6 As shown, the nozzle 4 is also provided with a nozzle 42 . An inner chamber 13 is embedded at the outlet of the material hole 11 towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com