Ball screw transmission device

A transmission device and ball screw technology, applied in the direction of transmission device, transmission device parts, transmission elements, etc., can solve the problems of many processing procedures, difficult processing, complex structure, etc., to reduce volume and weight, simple and reliable assembly, and transmission. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

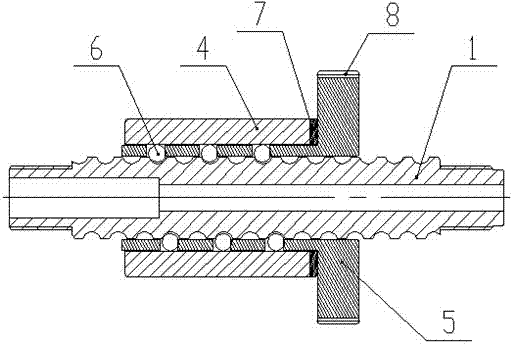

[0037] Such as figure 1 , image 3 , Figure 6 and Figure 7 As shown, a ball screw transmission device includes a screw rod 1 and a transmission assembly; the transmission assembly includes 4 nut outer sets and a cage 5, the inner surface of the nut sleeve 4 is processed into a smooth surface 41, and the nut sleeve 4 is installed on the outer circular surface of the cage 5, the inner wall of the nut jacket 4 is not provided with a raceway, and the smooth inner wall restricts the radial movement of the steel ball 6, so that the steel ball 6 forms a gap between the screw rod 1, the cage 5 and the nut jacket 4. A relatively closed space with a certain gap produces circular rolling; the nut jacket 4 is easy to process, and the requirements for processing equipment are greatly reduced; the cage 5 is processed with through holes 51, which can be evenly arranged, and the corresponding through holes 51 after the cage 5 is unfolded The center distance A of the hole 51 is an in...

Embodiment 2

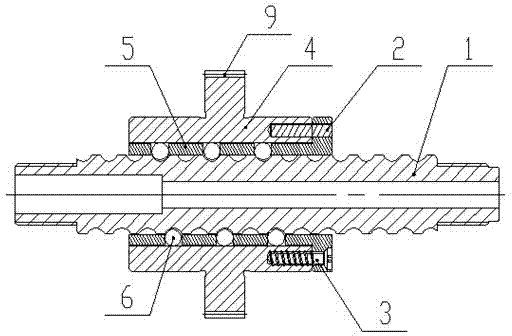

[0039] Such as figure 2 , Figure 4 , Figure 6 and Figure 7As shown, a ball screw transmission device includes a screw rod 1 and a transmission assembly; the transmission assembly includes a nut casing 4 and a cage 5, the inner surface of the nut casing 4 is processed into a smooth surface 41, and the nut casing 4 Installed on the outer circular surface of the cage 5, the inner wall of the nut jacket 4 is not provided with a raceway, and the smooth inner wall restricts the radial movement of the steel ball 6, so that the steel ball 6 forms a relative gap between the screw rod 1, the cage 5, and the nut jacket 4. A closed space with a certain gap produces circular rolling; the cage 5 is processed with a through hole 51, and the center distance A of the corresponding through hole 51 after the cage 5 is unfolded is an integral multiple of the pitch of the screw rod 1, and the nut sleeve 4 The smooth surface 41 and the upper surface of the cage 5 are fixed after being connec...

Embodiment 3

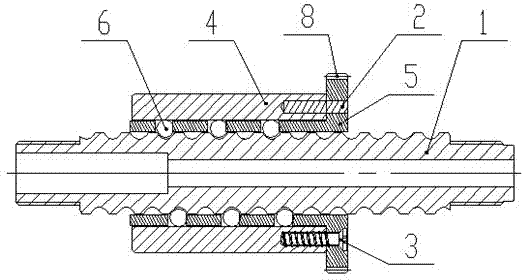

[0041] Such as Figure 5 , Figure 6 and Figure 7 As shown, a ball screw transmission device includes a screw rod 1 and a transmission assembly; the transmission assembly includes 4 nut outer sets and a cage 5, the inner surface of the nut sleeve 4 is processed into a smooth surface 41, and the nut sleeve 4 is installed on the outer circular surface of the cage 5, the inner wall of the nut jacket 4 is not provided with a raceway, and the smooth inner wall restricts the radial movement of the steel ball 6, so that the steel ball 6 forms a gap between the screw rod 1, the cage 5 and the nut jacket 4. A relatively closed space with a certain gap to produce circular rolling; the cage 5 is processed with a through hole 51, and the center distance A of the corresponding through hole 51 after the cage 5 is unfolded is an integer multiple of the pitch of the screw rod 1, and the nut is covered The smooth surface 41 of 4 and the upper surface of the cage 5 are fixed after being conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com