Automatic floating method of magnetic levitation rotor

A magnetic levitation rotor, magnetic levitation technology, used in bearings, shafts and bearings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

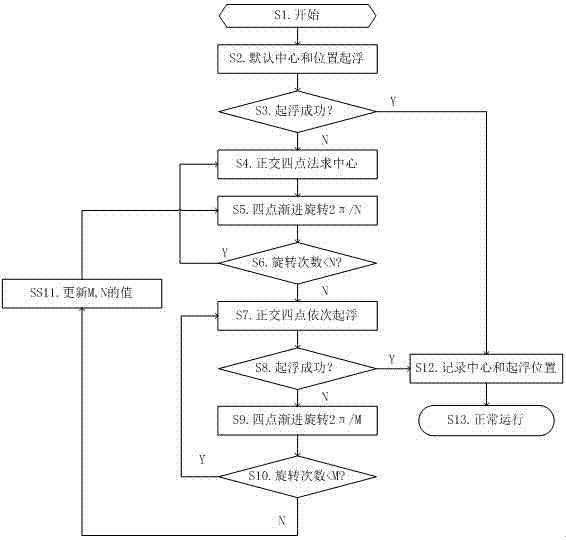

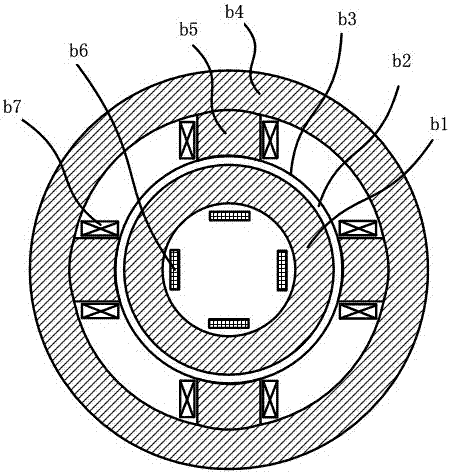

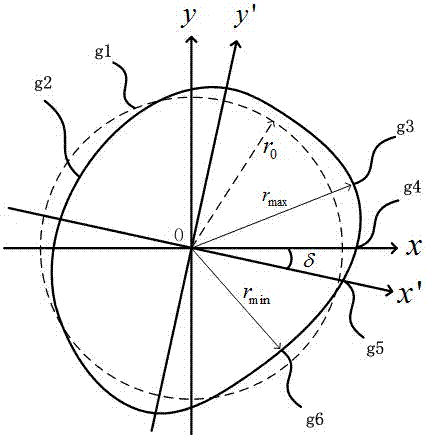

[0033] The invention discloses an orthogonal four-point progressive rotation method for a magnetic levitation rotor. Take four orthogonal points in the radial plane where the rotor is located, and use the magnetic levitation electromagnetic force to drive the rotor to these four points in sequence according to the established steps. Then four points are simultaneously rotated around the rotating shaft of the rotor by a given angle to generate new four points, and then the rotor is made to these new four points successively. The invention discloses an automatic floating method based on an orthogonal four-point progressive rotation magnetic levitation rotor. Firstly, use the orthogonal four-point progressive rotation method to find the center of suspension, and then use the orthogonal four-point progressive rotation method to find the floating position and try to levitate. If the levitation is unsuccessful, modify the progressive angle of the progressive rotation and re-find th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com