Combined silencing, sound-insulating and vibration-isolating device of centrifugal fan

A centrifugal fan and composite technology, applied in parts of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., can solve environmental noise pollution in industrial enterprises, affect the service life of motors and circuit safety, Unable to reduce the noise of the metal shell of the fan, etc., to achieve the effect of improving the noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

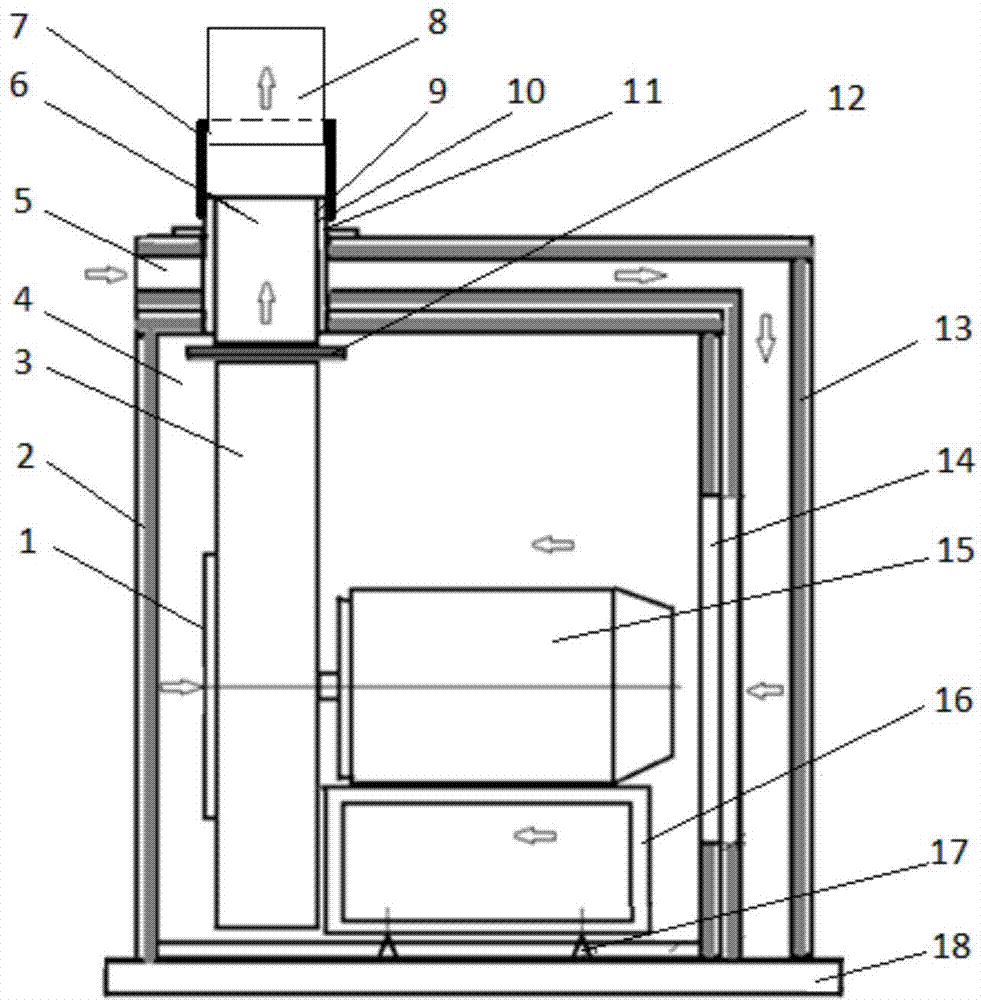

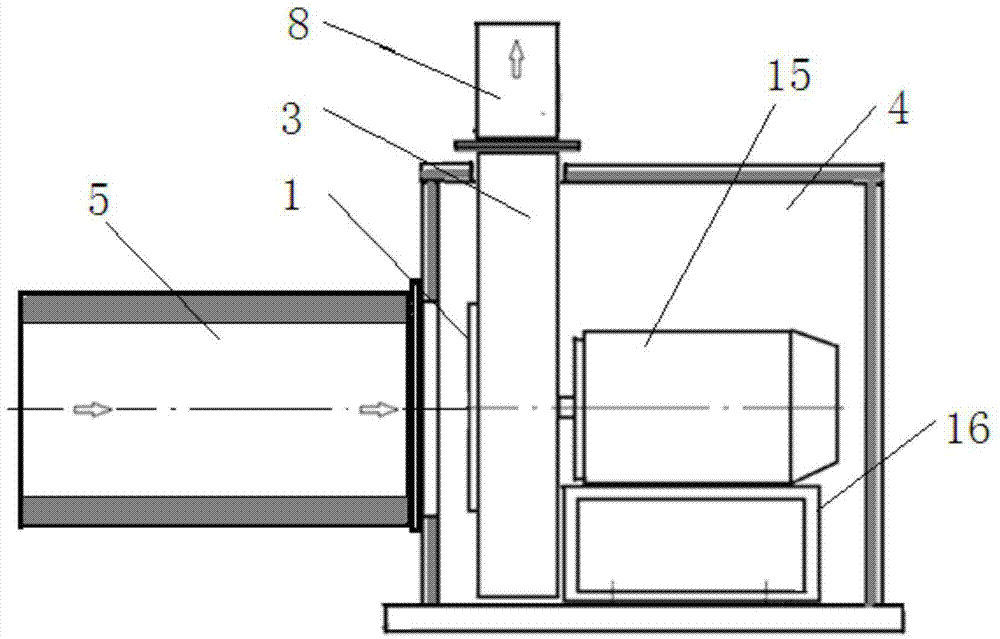

[0020] Such as figure 1 As shown, the sound-insulation and vibration-isolation composite device of the centrifugal fan includes a muffler 5, a sound-insulation cover 4 and a vibration isolator 17. Outside the air outlet 14, other surfaces are all sealed to each other. The air inlet of the muffler is located on one side of the sound insulation cover 4, and the muffler air outlet 14 is located on the other side of the sound insulation cover 4. The muffler parts on the two sides Constitute a muffler elbow, form an L-shaped muffler channel, and increase the muffler capacity.

[0021] The exhaust hole of the sound insulation cover is composed of an inner exhaust connecting pipe 9 and an outer exhaust connecting pipe 10. The inner exhaust connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com