Pretreatment method for improving compactness of coal seam water injection hole

A coal seam water injection and pretreatment technology, which is applied in earthwork drilling, sealing/packing, wellbore/well components, etc., can solve the problems of coal not being wet, water loss, weakening coal water injection and dust reduction, etc., to achieve protection Effects of life health, improvement of humidity level, and reduction of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

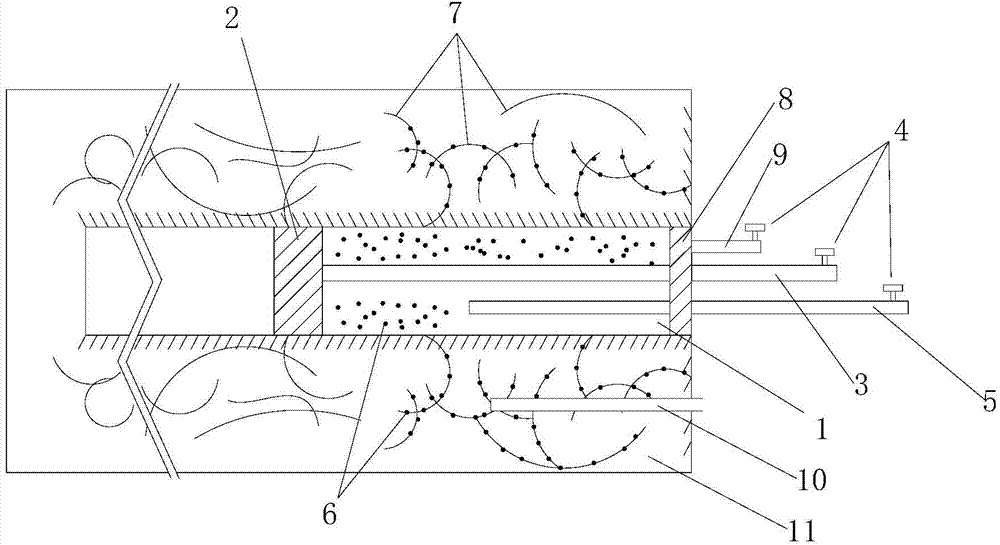

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, after the coal seam water injection hole 1 is formed by drilling the coal seam 11, the coal seam is deformed and displaced due to the damage to the coal seam 11 caused during the drilling process, resulting in the expansion and development of the fracture group 7 in the coal seam around the coal seam water injection hole 1, Some develop to the position of the coal wall to communicate with the outside world, and some communicate with the bolt hole 10 that has been formed before. Therefore, in the next water injection process, the water will be lost through these cracks, so that the coal seam can be injected with water to wet the coal body. Significantly decreased. Pretreatment method of the present invention is specifically:

[0021] (1) The first gas expansion capsule 2 is connected to the first air pressure pipe 3, and the first gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com