Assembling self-bearing die of ribbed floor

An assembled, self-supporting technology, used in floors, building components, buildings, etc., can solve the problems of poor fire resistance, short fire resistance time, poor seismic performance, etc. Stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

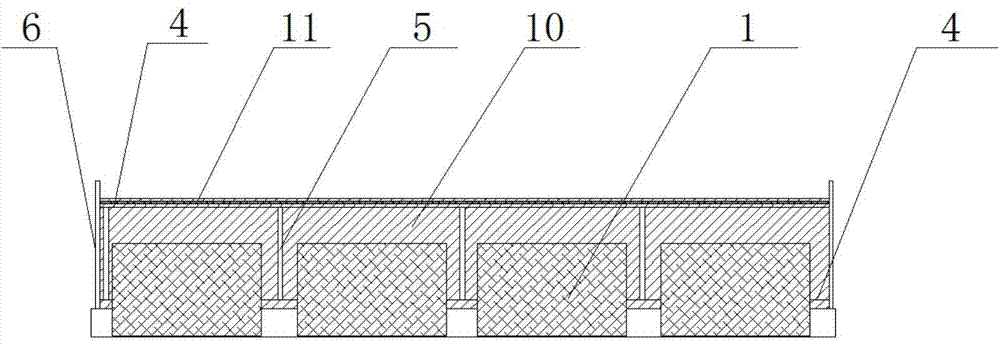

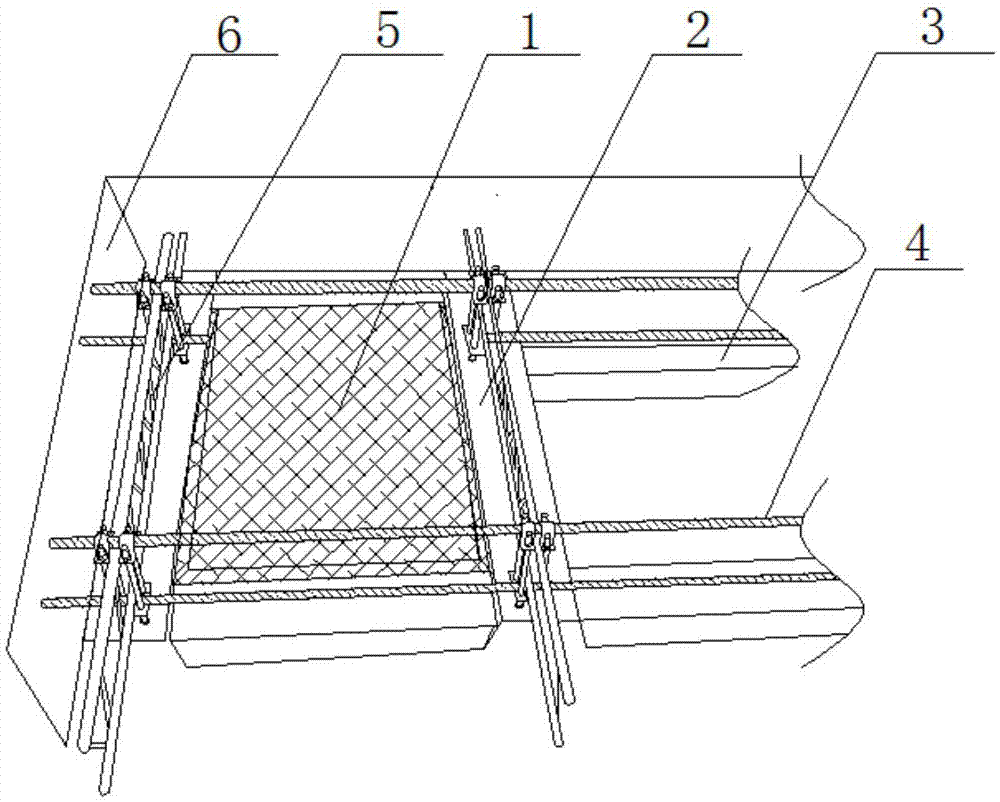

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] like figure 1 and figure 2 As shown, the present invention provides an assembled self-supporting mold for a densely ribbed floor slab comprising an inner core 1 and an outer mold, and the outer mold includes a bottom mold and a baffle plate 6 arranged on the outer edge of the bottom mold; the bottom mold has a net grid structure, forming a plurality of bottom mold cavities; the inner core 1 is respectively arranged in each bottom mold cavity, and there is space between the baffle plate 6 and the inner core 1 and between the inner core 1 and the inner core 1. There is a casting gap, and the space surrounded by the baffle plate 6, the bottom mold and the inner core 1 constitutes a casting space 10; a steel bar truss structure is fixedly arranged on the bottom mold and in the casting space 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com