Soft soil foundation seabed fixed mounting construction method of water building ocean fixed platform

A technology for offshore platforms and soft soil foundations, which is applied in construction, water conservancy engineering, infrastructure engineering and other directions to achieve significant economic benefits and less damage to the environment and ecology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

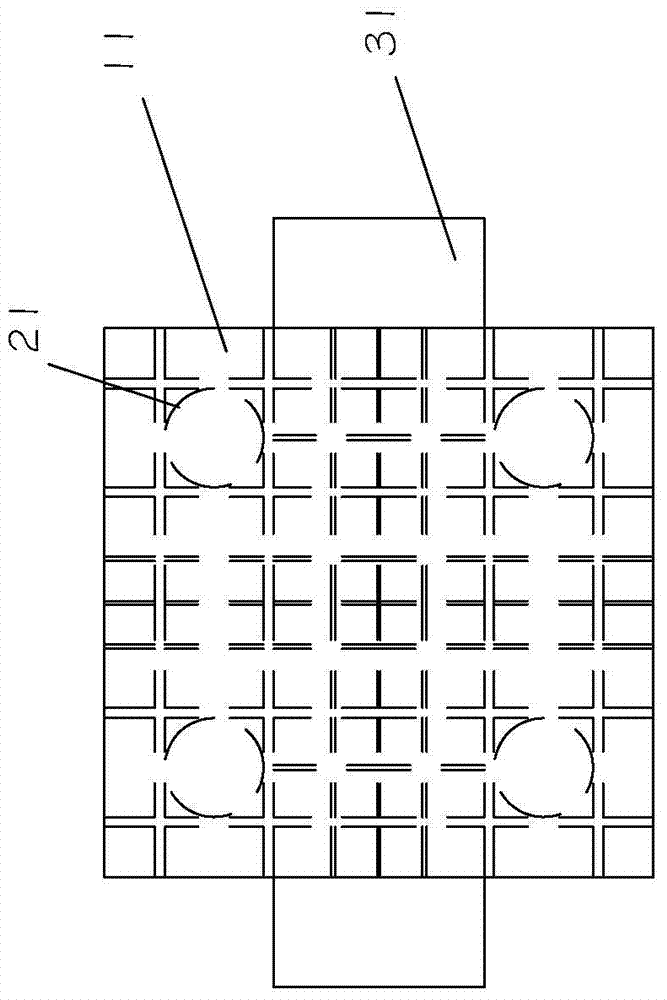

[0082] A platform of 50m×50m is supported by four buoyancy cylinders with a diameter of 8.8m, with a total weight of 8,500 tons. The platform is expected to support a total of 12,000 tons of building loads and live loads. Supported by rock-socketed piles, the water depth of the installation site is 8 meters. The geological data are shown in Table 1:

[0083] Table 1: Geological Standard Penetration Number of Installation Site (SPT N-Value)

[0084] Depth (m) Rock and soil name Measured penetration volume (cm) Average measured hits (N) 5-10.75 silt 30 1 12.30-22.70 Silty Clay 30 10 26.10-30.2 silt 30 49 32.4-36.65 Silty Clay 30 17 38.6-51.25 fine-medium sand 30 58 53.05-58 Gravel 10 150

[0085] It can be seen from Table 1 that the 5m of the seabed is silt, which cannot bear the self-weight of the platform when it is installed. Steel cylinders are used as temporary supports. In the case of ignoring the surface...

example 2

[0093] Instead of using pile foundations, the method of replacing bearing materials in steel cylinders is adopted. Among them, the load is directly transmitted from the bottom of the buoyancy cylinder wall to the displacement material column and then to the bearing layer on the seabed.

[0094] Firstly, the bearing layer is searched according to the geological data. The depth of the strongly weathered rock formation is 58m, and the number of standard penetration hits is >200.

[0095] Taking the depth of the strongly weathered rock formation as the depth of vibration of the steel cylinder, the total length of the steel cylinder is 2+8+(58-5)=63m, of which 2m on the water surface, 8m in the water, and 53m buried in the seabed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com